Polishing OEM Throttle Body

#1

Hey guys.

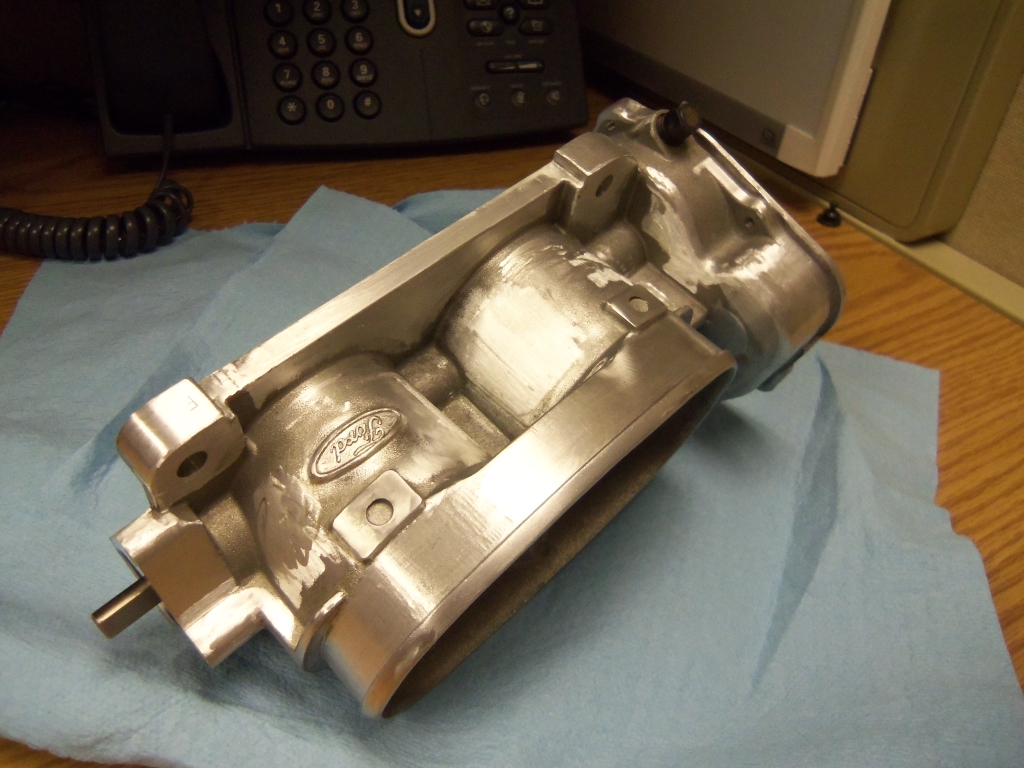

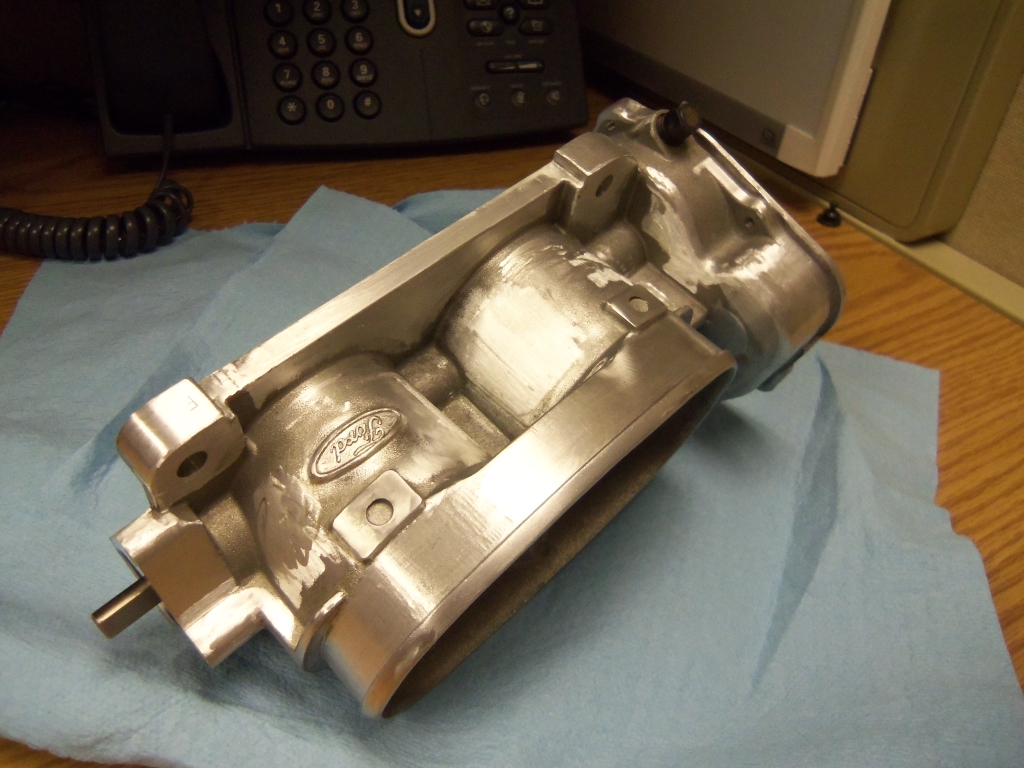

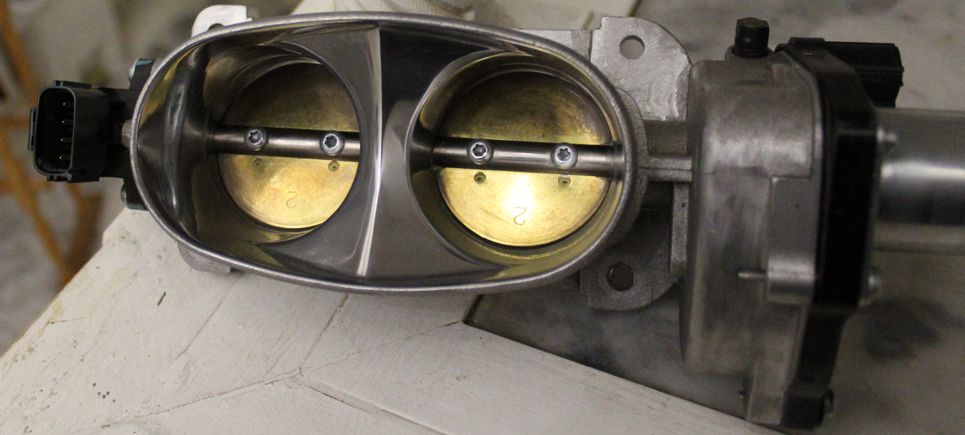

I'm polishing the throttle body on my 2008 Mustang GT. It's a cast aluminum piece with lots of little nooks and crannies to get into. I've never polished anything before, so I'm kind of learning as I go along. I've got 4 hours or so into it right now, and I'm just trying to get through the roughness of the casting down to a smooth surface. I'm using a Dremel as my tool of choice, but will likely have to hand sand to get all of the surfaces smooth enough to polish.

Anyway, here are a few pictures of my progress so far. Most of the sanding was done with the course sanding drum of the dremel. Other sanding was done with those sanding discs (they work well, but wear out very quickly).

I cant wait until I get down to a smooth surface and then I can really begin working up the grits to get a mirror finish.

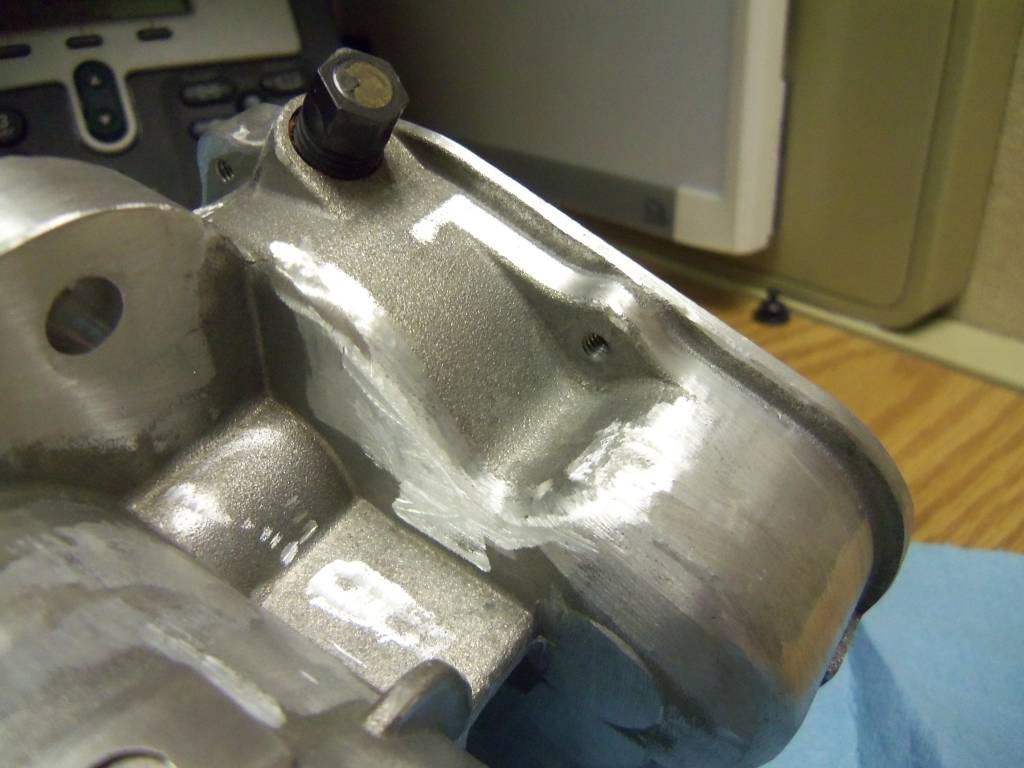

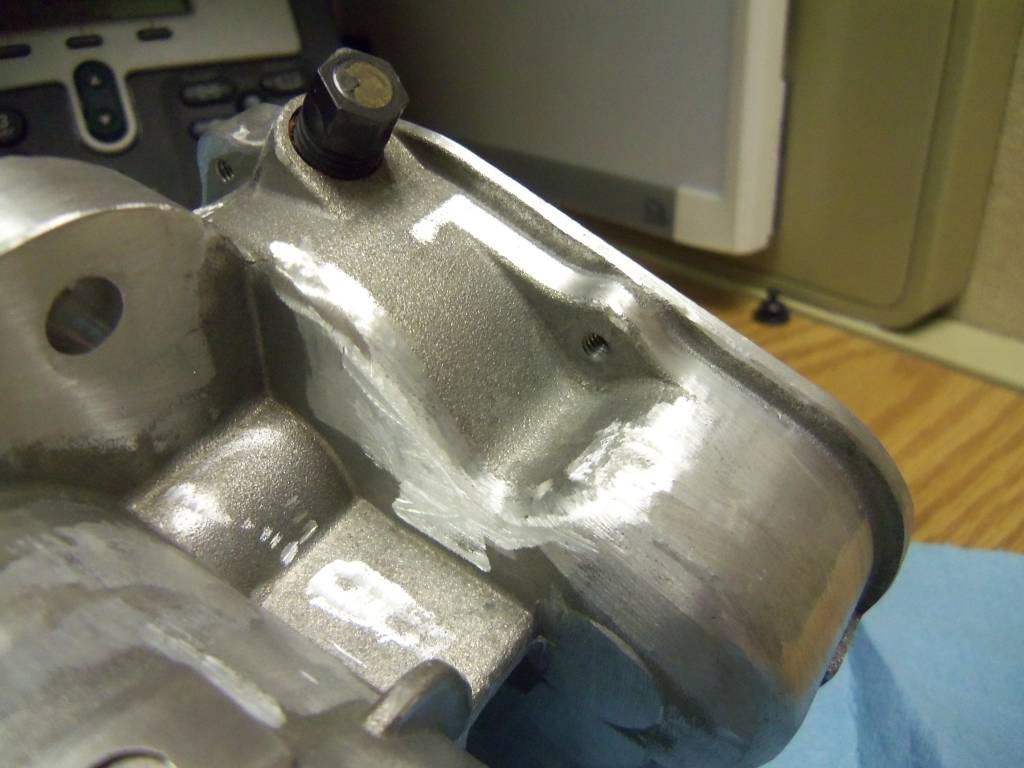

Here is one final photo that best shows the type of surface I'm starting with, and how much of a pain it is to get down to smooth aluminum:

I'm polishing the throttle body on my 2008 Mustang GT. It's a cast aluminum piece with lots of little nooks and crannies to get into. I've never polished anything before, so I'm kind of learning as I go along. I've got 4 hours or so into it right now, and I'm just trying to get through the roughness of the casting down to a smooth surface. I'm using a Dremel as my tool of choice, but will likely have to hand sand to get all of the surfaces smooth enough to polish.

Anyway, here are a few pictures of my progress so far. Most of the sanding was done with the course sanding drum of the dremel. Other sanding was done with those sanding discs (they work well, but wear out very quickly).

I cant wait until I get down to a smooth surface and then I can really begin working up the grits to get a mirror finish.

Here is one final photo that best shows the type of surface I'm starting with, and how much of a pain it is to get down to smooth aluminum:

#3

I would like to do the inside. I wouldn't want to do anything that would require a tune as I don't have one right now. I think that as long as I don't change the diameter of the machined area where the butterflies are, I should be OK without a tune. Is that correct? I know for CAI's, as long as the MAF diameter stays the same, then you don't need a tune. I'm applying the same idea here. Tell me if I'm wrong though.

I noticed that there is a little ridge or lip where the cast surface goes into the machined bores of the throttle body. I imagine smoothing that lip out along with an overall smooth surface would at least flow a little better. It appears like there is plenty of room to smooth that out and not affect the diameter by the butterfly valves.

I noticed that there is a little ridge or lip where the cast surface goes into the machined bores of the throttle body. I imagine smoothing that lip out along with an overall smooth surface would at least flow a little better. It appears like there is plenty of room to smooth that out and not affect the diameter by the butterfly valves.

#5

It's amazing how much shine it gets even with a rough 80 grit or so sanding.

I did some spots by hand with 220 grit. All the scratches were going in the same direction, and it created that awesome brushed aluminum look. It looked really cool, but isn't the end look that I'm going for.

I did some spots by hand with 220 grit. All the scratches were going in the same direction, and it created that awesome brushed aluminum look. It looked really cool, but isn't the end look that I'm going for.

#6

I wouldn't mess with the inside unless you get extrude honing done like how they do a head port and polish, with really thick paste under pressure. Anything by hand is just asking for problems when dealing with air flow.

#7

#10

I never actually installed it... I had gotten the Ford racing 62mm throttle body, and figured I would practice polishing with the stock one. Plannibg on selling it or trading it at some point.