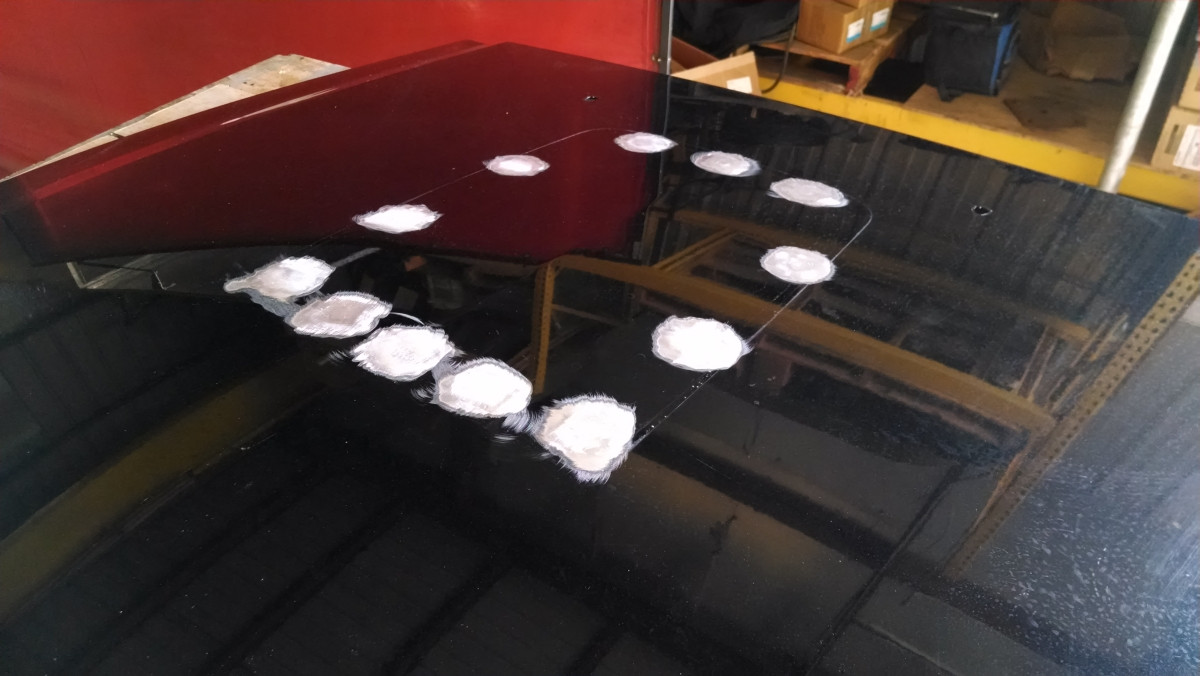

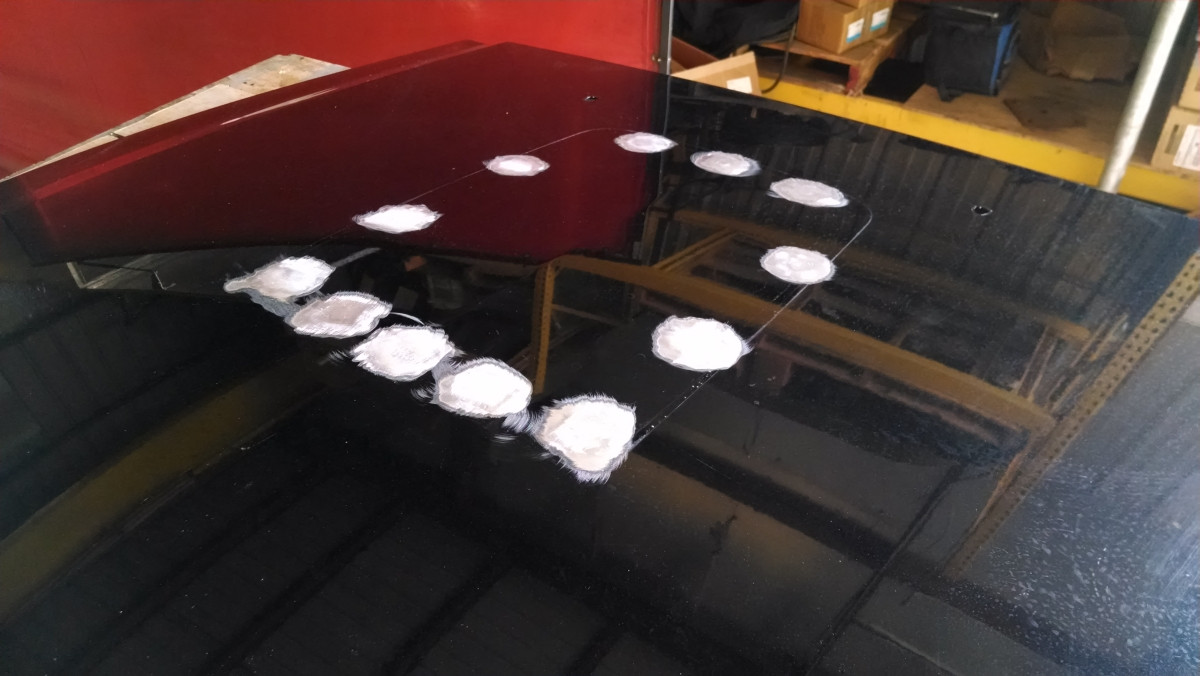

Hood hole filling

#11

Took the majority of the weld down with 120 grit 4" flapper wheel on my electric dewalt side grinder then finished it with a 40 grit 2" sanding wheel on my pneumatic angle-die grinder till I couldnt feel the weld bump anymore. Did the back first, then the front. Next is body filler and blocking.

These hoods are super nice, I never realized until I started working on them. Incredibly light. I didn't put a mic on it but it's gotta be made of at least 22GA if not thinner.

These hoods are super nice, I never realized until I started working on them. Incredibly light. I didn't put a mic on it but it's gotta be made of at least 22GA if not thinner.

Last edited by gmoran1469; 06-29-2014 at 06:09 PM.

#12

That's why I don't have an aftermarket hood. Fiberglass hoods weigh more than the aluminum stocker. I want to weld up the wiper nozzle holes and paint my stripes on. I don't have a welder yet and was considering brazing them up with some alumiweld rods. Not sure if welding aluminum is something for a beginner. I also need to do the spoiler holes on the trunk lid.

#13

That's why I don't have an aftermarket hood. Fiberglass hoods weigh more than the aluminum stocker. I want to weld up the wiper nozzle holes and paint my stripes on. I don't have a welder yet and was considering brazing them up with some alumiweld rods. Not sure if welding aluminum is something for a beginner. I also need to do the spoiler holes on the trunk lid.

#14

Wow, thanks for that advice! Maybe I will just leave the wiper nozzles alone and just paint the stripes. How about the trunk lid? I believe that is steel. I know brazing is not the preferred method, but I like to do things myself. Would the same thing apply if I brazed the holes there or would the steel warp just as badly as the aluminum?

#15

Wow, thanks for that advice! Maybe I will just leave the wiper nozzles alone and just paint the stripes. How about the trunk lid? I believe that is steel. I know brazing is not the preferred method, but I like to do things myself. Would the same thing apply if I brazed the holes there or would the steel warp just as badly as the aluminum?

#16

Hood goes to the paint shop next week, should get it back around the weekend after that. Got some favors I can call in so no cost to me (woot!)

Last edited by gmoran1469; 07-10-2014 at 03:27 PM.

#17

I've tried brazing car sheet metal, it makes a real mess. Even a cheap MIG welder is much better. You can put a block of copper flush against the opposite side that you are welding from, MIG will not stick to the copper and you will not blow through the sheet metal. You can flatten a piece of copper water pipe enough for a small project.

#18

I've tried brazing car sheet metal, it makes a real mess. Even a cheap MIG welder is much better. You can put a block of copper flush against the opposite side that you are welding from, MIG will not stick to the copper and you will not blow through the sheet metal. You can flatten a piece of copper water pipe enough for a small project.

#19

Hood back from paint. Even the underside

There are two imperfections in the paint and a couple fish eyes but a free paint job is a free paint job so I won't complain.

There are two imperfections in the paint and a couple fish eyes but a free paint job is a free paint job so I won't complain.

Last edited by gmoran1469; 07-21-2014 at 06:01 PM.

Thread

Thread Starter

Forum

Replies

Last Post

jwog666

Pipes, Boost & Juice

11

12-27-2021 08:09 PM