how much do you torque your wheels?

#41

Most consumer-level 40 year old torque wrenches would be beam types that won't drift out of calibration unless the wrench is obviously damaged. About the worst thing likely to happen is the pointer gets bent and doesn't "zero" on the 0, which calls for a fix about as simple as DIY adjustments get.

Lug nuts securing alloy wheels will loosen slightly. Possibly more than just "slightly" given enough wheel swapping and torque cycles (trust me on this last one).

Norm

Lug nuts securing alloy wheels will loosen slightly. Possibly more than just "slightly" given enough wheel swapping and torque cycles (trust me on this last one).

Norm

Last edited by Norm Peterson; 11-18-2014 at 11:23 AM.

#42

OK fine. I didn't torque wrench my 4 spoiler bolts... because it's not a truely important part of the car, if the part is mechanically functioning, then yes, it gets torque wrenched. Sway bars, rod ends, struts, A-Arms, etc... if it's just a screw holding a wire - no, but if it has a supplied spec and is part of the function of the car, then yes, I do. call me what you want, but thats how I work on my car for piece of mind

#45

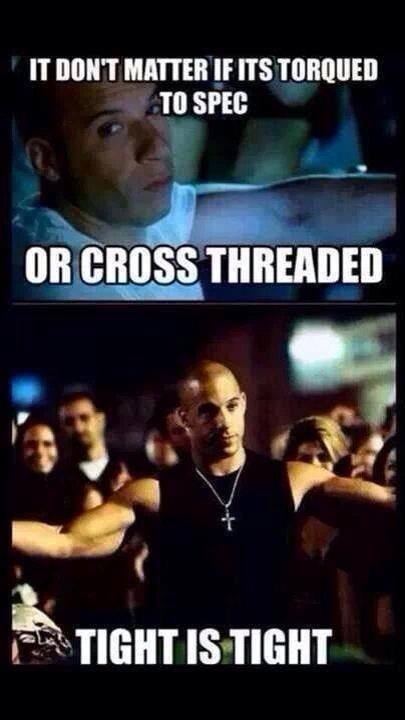

Ah yes, "common sense" and "tight is tight", never mind that you hands aren't going to know the difference between a 3/8-UNC Grade 2 bolt and a fine-thread M10 in 12.9 until they break one of them.

Offhand, the only fasteners that I know of where "oops" is a torque spec are the nuts that hold your replacement toilet seat in place on the porcelain.

Norm

Offhand, the only fasteners that I know of where "oops" is a torque spec are the nuts that hold your replacement toilet seat in place on the porcelain.

Norm

#46

Most consumer-level 40 year old torque wrenches would be beam types that won't drift out of calibration unless the wrench is obviously damaged. About the worst thing likely to happen is the pointer gets bent and doesn't "zero" on the 0, which calls for a fix about as simple as DIY adjustments get.

The accuracy of a beam-type torque wrench is ballpark at best. But, for most things it's accurate enough. I wouldn't do anything on an airplane and I wouldn't do heads, rod bolts, crank bolts etc. with a beam type. But I still have mine from the old days and use it for things where lots of leverage is needed and close accuracy is not required. I tested mine and it's within 20 ft lbs @ 100-120.

#47

I'd bet that it's been within the same 20 ft-lbs @ 100 - 120 all its life, save for any unusually warm or cold times where the steel's modulus varied enough to measurably affect the beam deflection. Most of us older guys have used these wrenches on any and all engine fasteners, and I guess that at least means that the fasteners were all drawn up more consistently than just "gutentite", and that with a little luck might even have been fairly close to spec.

Norm

Norm

Last edited by Norm Peterson; 11-18-2014 at 03:54 PM.

#48

I hate to rain on everyone's parade here but torque wrenches are somewhat unreliable. In our facilities, we re-calibrate/adjust/repair/replace torque wrenches every 60 days because we were finding that at 6 month intervals, we would have some that drifted out of spec. When that happened, we would have to recapture every assembly where the torque wrench was used and re-torque the fasteners. If you are using a torque wrench you've had for 40 years and have never had it calibrated, you might as well use a socket nailed to a 2 x 4. I've even seen brand new (expensive) torque wrenches that can't repeat within +/- 5%.

That said, nobody had a torque wrench when my father changed wheels through the 40's-80's or when I did clear up until maybe 10 years ago. Never had a wheel or nut come loose.

That said, nobody had a torque wrench when my father changed wheels through the 40's-80's or when I did clear up until maybe 10 years ago. Never had a wheel or nut come loose.

The twist setting and "Click!" indication wrenches are not as reliable, especially if the tool gets used A LOT.

Funny; the "Click!" indication torque wrenches are more expensive than the plain beam and pointer wrenches.

Back in the 40s-80s, the idea of warped rotors was not as much a concern since more cars had thick drum brakes. Those most likely were impervious to warping from over-tightening the lugnuts.

I do believe that the disc brakes from even the pre-80s cars required you to pay attention to over-tightening.

#49

Tolerances were much looser back when us old guys were young. As the Quality Assurance Manager of a mid-sized Aerospace manufacturer for 25 years, I can attest to that. Most tolerances of any consequence are roughly 1/4 to 1/3 what they were in the 50's-80's. I understand through industry scuttlebutt that the auto manufactures have followed suit. It you want to use old school technology on modern applications and tolerances, I suppose it's better than nothing. But if you are doing serious work, a little more serious tooling is called for in my opinion. You won't find many beam style torque wrenches in serious machine shops IMO.