if you adjusted you pinion angle, come in!

#21

If it's there with the stock driveshaft, then I don't think adjusting the pinion angle will totally fix the problem. Like I said, my stock clutch/pressure plate/flywheel was my source of vibration. I'm sure I warped one of those three things by beating on the car.

#22

i think i'll install the adj lca's while the stock ds is still installed and play around with that first. if i can make any improvement with the stocker, then i'll probably go forward with re-re-re-re-installing the alum ds.

#23

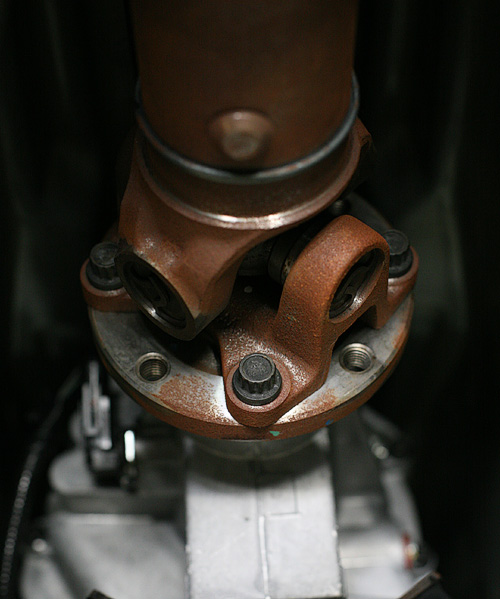

Did you turn the driveshaft at the transmission or rear end? I had put my stock shaft back in with the transmission flange in a different position than it was at stock. Just that caused a slight vibration over 70mph.

Luckily I had taken a picture of my driveshaft before I removed it the first time and was able to put it back exactly as it was by looking at the picture and the dots on the flange.

I still had the bolts in the same holes, but I had the flange turned 90 degrees. Turning it back like it was fixed the problem. that green dot on the bottom of the flange saved me a lot of aggravation.

Needless to say, I installed my denny's drive shaft just like that.

#25

Someone had posted this link an an old post.

I think It was CrazyAl.

http://www.cherod.com/mustang/HowTo/LCA%20_adj.htm

I found that since I have such a stiff suspension setup (all the control arms replaced with poly/sperhical joints) I needed to remove a lot of the pinion angle. Since the suspension is so stiff the axle does not twist much under load so it doesn't need much negative pinion angle anymore. The link explains it all...

I'm at about 1.5 degrees now and its much better.

I have a Coast Driveline 1 piece btw.

I will say this. The driveshaft makes EVERYTHING sound different on the car.

Even starting the engine sounds a lot different. I basically added a large aluminum resonator chamber down there...

It's mostly because there's such a stiff connection between the axle and the body with all the sperical ends.

It's time for some Dynamat...

I think It was CrazyAl.

http://www.cherod.com/mustang/HowTo/LCA%20_adj.htm

I found that since I have such a stiff suspension setup (all the control arms replaced with poly/sperhical joints) I needed to remove a lot of the pinion angle. Since the suspension is so stiff the axle does not twist much under load so it doesn't need much negative pinion angle anymore. The link explains it all...

I'm at about 1.5 degrees now and its much better.

I have a Coast Driveline 1 piece btw.

I will say this. The driveshaft makes EVERYTHING sound different on the car.

Even starting the engine sounds a lot different. I basically added a large aluminum resonator chamber down there...

It's mostly because there's such a stiff connection between the axle and the body with all the sperical ends.

It's time for some Dynamat...

#26

Someone had posted this link an an old post.

I think It was CrazyAl.

http://www.cherod.com/mustang/HowTo/LCA%20_adj.htm

I found that since I have such a stiff suspension setup (all the control arms replaced with poly/sperhical joints) I needed to remove a lot of the pinion angle. Since the suspension is so stiff the axle does not twist much under load so it doesn't need much negative pinion angle anymore. The link explains it all...

I'm at about 1.5 degrees now and its much better.

I have a Coast Driveline 1 piece btw.

I will say this. The driveshaft makes EVERYTHING sound different on the car.

Even starting the engine sounds a lot different. I basically added a large aluminum resonator chamber down there...

It's mostly because there's such a stiff connection between the axle and the body with all the sperical ends.

It's time for some Dynamat...

I think It was CrazyAl.

http://www.cherod.com/mustang/HowTo/LCA%20_adj.htm

I found that since I have such a stiff suspension setup (all the control arms replaced with poly/sperhical joints) I needed to remove a lot of the pinion angle. Since the suspension is so stiff the axle does not twist much under load so it doesn't need much negative pinion angle anymore. The link explains it all...

I'm at about 1.5 degrees now and its much better.

I have a Coast Driveline 1 piece btw.

I will say this. The driveshaft makes EVERYTHING sound different on the car.

Even starting the engine sounds a lot different. I basically added a large aluminum resonator chamber down there...

It's mostly because there's such a stiff connection between the axle and the body with all the sperical ends.

It's time for some Dynamat...

#27

Here is what resulted..... I took the shaft out and reversed like I wanted to anyways and checked my pinion....was at -1.. I changed it to -2 as I think -3 is too much given the parts I have . I bolted in the shaft and ran it up on the blocks to check and there was some runout...I then rotated it and there was still some.....I then tried barely snugging the bolts and while rotating by hand tapped the flange a full 2-3 turns. I then snugged them a bit more and checked by running and my god the frikin thing is true as could be ! Did the same to the back and then bolt by bolt torqued them with locktite.....re ran it and this morning on the way to work could make 90 + with no vibration ....!!!!!

Bottom line ...I think the flange is so snug on the little shoulder that it must get askew and stay that way ever so minimal....tap it and it seats true !!

Bottom line ...I think the flange is so snug on the little shoulder that it must get askew and stay that way ever so minimal....tap it and it seats true !!

#28

Here is what resulted..... I took the shaft out and reversed like I wanted to anyways and checked my pinion....was at -1.. I changed it to -2 as I think -3 is too much given the parts I have . I bolted in the shaft and ran it up on the blocks to check and there was some runout...I then rotated it and there was still some.....I then tried barely snugging the bolts and while rotating by hand tapped the flange a full 2-3 turns. I then snugged them a bit more and checked by running and my god the frikin thing is true as could be ! Did the same to the back and then bolt by bolt torqued them with locktite.....re ran it and this morning on the way to work could make 90 + with no vibration ....!!!!!

Bottom line ...I think the flange is so snug on the little shoulder that it must get askew and stay that way ever so minimal....tap it and it seats true !!

Bottom line ...I think the flange is so snug on the little shoulder that it must get askew and stay that way ever so minimal....tap it and it seats true !!

i may try the "tap test" this weekend. i need to make this thing work, it costs too much to leave it sitting there on the garage floor.

#29

I have the flange in the rear no adapter....vitually the same as the front ....

I did file the flange a bit as the runout on it was like 4thou...I used a dial indicator....

Try the tap thing ...might just do the trick for you too

I did file the flange a bit as the runout on it was like 4thou...I used a dial indicator....

Try the tap thing ...might just do the trick for you too

#30

she scored a 99, it's the highest a person can score on the test. the average score for those who are admittied to the UT Austin pharmacy college is an 85!

needless to say, we're celebrating tonight!