Broken motor mount on block, I'm gonna be sick

#1

This is the best place I figured to post this since the motor is a roller 302 similar to a foxbody and one of y'all might've run into this problem before.

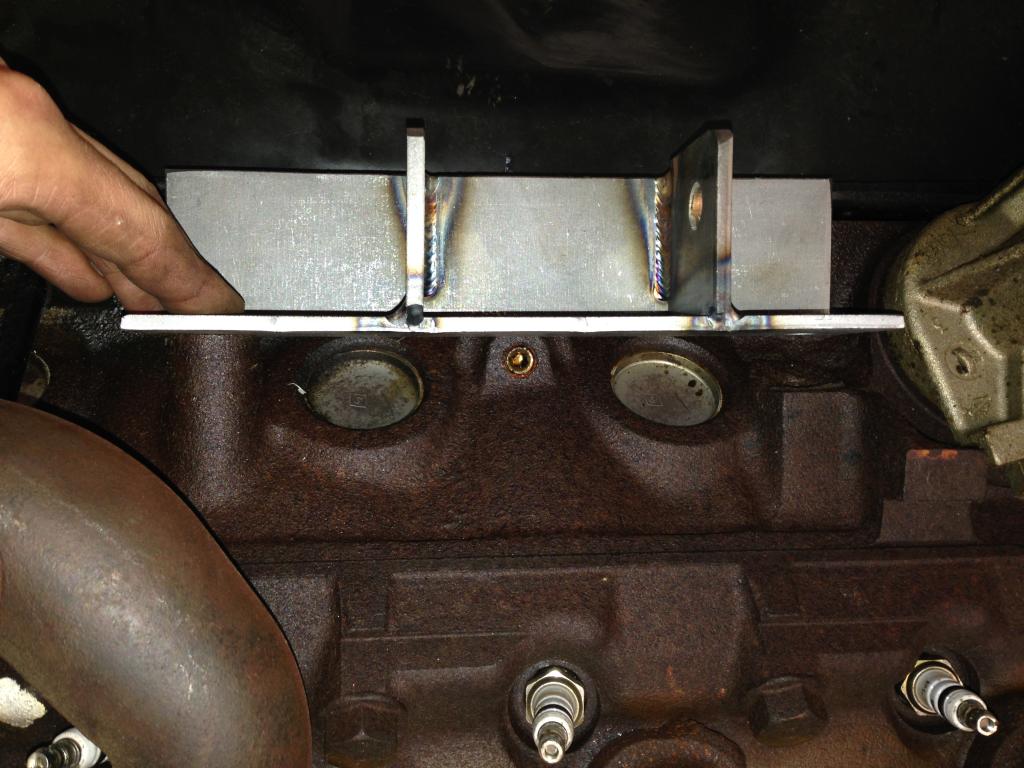

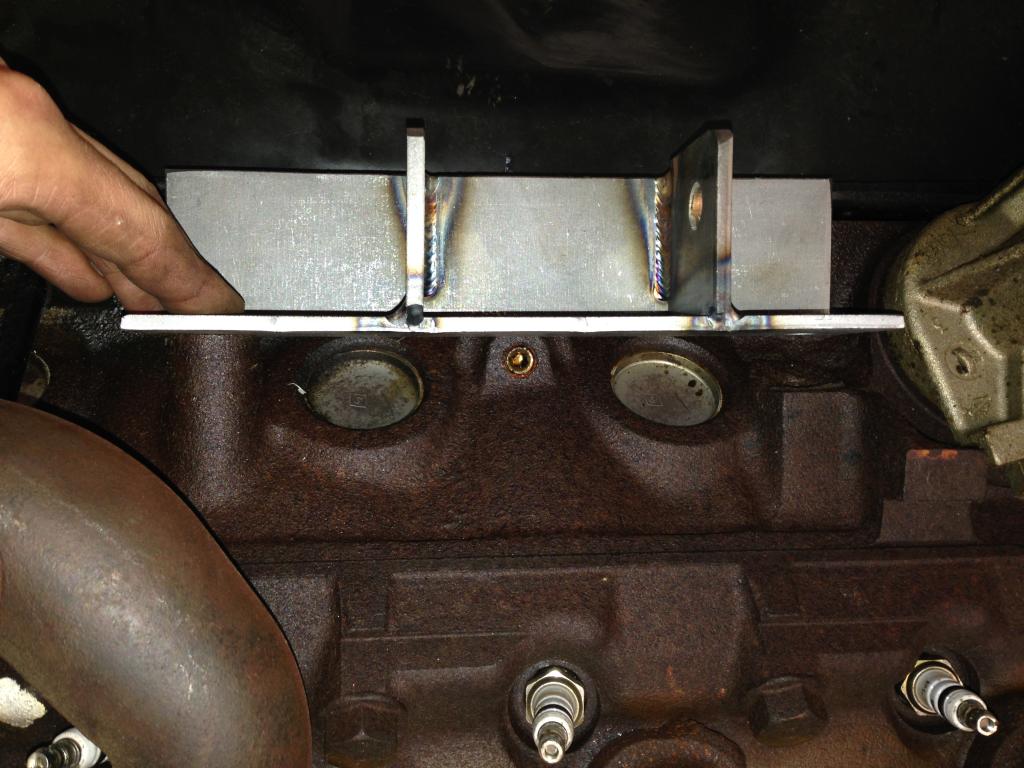

I purchased a 99 Explorer motor from a friend that got the motor at a salvage yard and go to tear it down today, well little did I know, the block is broken where the motor mount bolts to... My heart sunk... The motor is so clean, 120,xxx miles, GT40P heads, etc. although there aren't many threads in the hole I'm thinking I can grind the broken part flat and weld on a metal bushing, the correct height, and either use the threads that are left or cut new threads all the way down through the new bushing and block. I wouldn't even know if that would hold, but it seems like it'd be worth the try Just kinda depressed here guys. I really dont wanna scrap the motor. I dont have THAT much in it, but I'd like to use it.

Just kinda depressed here guys. I really dont wanna scrap the motor. I dont have THAT much in it, but I'd like to use it.

Here's some pictures.

Thanks guys

I purchased a 99 Explorer motor from a friend that got the motor at a salvage yard and go to tear it down today, well little did I know, the block is broken where the motor mount bolts to... My heart sunk... The motor is so clean, 120,xxx miles, GT40P heads, etc. although there aren't many threads in the hole I'm thinking I can grind the broken part flat and weld on a metal bushing, the correct height, and either use the threads that are left or cut new threads all the way down through the new bushing and block. I wouldn't even know if that would hold, but it seems like it'd be worth the try

Just kinda depressed here guys. I really dont wanna scrap the motor. I dont have THAT much in it, but I'd like to use it.

Just kinda depressed here guys. I really dont wanna scrap the motor. I dont have THAT much in it, but I'd like to use it. Here's some pictures.

Thanks guys

#2

iirc to weld cast iron you have to heat it up cherry hot then weld on it. broken bosses are pretty common in vehicles they have been hit in the front end...

also you could always run a block plate in the front of the motor if you have to

also you could always run a block plate in the front of the motor if you have to

#4

Yeah, I asked around yesterday, and now understand it takes a little bit more than just your average mig welder. I'd attempt the fix, but it would be something I'd always worry about going aroung corners, hitting bumps, launching the car, etc. My friend is gonna call the salvage yard back to see if they will honor a warranty on the motor. I've found a ton of stuff missing on the motor anywho. Injectors are gone, coil packs missing, etc. It looks as if this motor was set aside for a parts motor till someone ordered an assembled engine and my friend got the crap motor that had a bunch of parts off it. Also, the upper intake is cracked at a mounting point, which does suggest, like 'rmodel65' said, a front impact could have happened. But never the less not impressed by any means. Hopefully he'll sort it out and I'll have another 5.0 this clean ready to tear down. Thanks for the suggestions guys, and I'm still open to any others that have other ideas. I feel like getting a machine shop to fix the block may be counterproductive as far as cost goes, but I'll work with what I got.

Last edited by 65mechanic; 10-20-2014 at 06:49 AM.

#5

Hello;

Major bummer, however, one good thing is that it looks like it has at least 4 threads in it, if so, one option is to flatten it and use a bottoming tap or cut a tap off and thread the hole as deeply as you can. Use a grade 8 bolt and measure the exact length you need then shorten the bolt so it has around 1 turn before it is fully bottomed out. Don’t taper the end of the bolt after you shorten it.

Bolt it on with the mount and spacer and proper torque to make sure the boss won’t crack. If it holds then install it like that and put a chain or something on that side mounted to a front cylinder head boss, then to the frame etc., with just a little play in it so when the engine is under heavy load, the chain will take a lot of the load instead of that boss.

Also, if you are considering using urethane mounts I wouldn’t do that with that mount on that side anyway, however, a urethane mount on the other side will help to reduce side movement of the engine which will also help.

As mentioned, a very good cast iron welder can weld a boss on that, but even if you hand him the boss, it still might cost close to $200.00.

It should also be done with a water cooled tig welder and not all "welders" have one.

Major bummer, however, one good thing is that it looks like it has at least 4 threads in it, if so, one option is to flatten it and use a bottoming tap or cut a tap off and thread the hole as deeply as you can. Use a grade 8 bolt and measure the exact length you need then shorten the bolt so it has around 1 turn before it is fully bottomed out. Don’t taper the end of the bolt after you shorten it.

Bolt it on with the mount and spacer and proper torque to make sure the boss won’t crack. If it holds then install it like that and put a chain or something on that side mounted to a front cylinder head boss, then to the frame etc., with just a little play in it so when the engine is under heavy load, the chain will take a lot of the load instead of that boss.

Also, if you are considering using urethane mounts I wouldn’t do that with that mount on that side anyway, however, a urethane mount on the other side will help to reduce side movement of the engine which will also help.

As mentioned, a very good cast iron welder can weld a boss on that, but even if you hand him the boss, it still might cost close to $200.00.

It should also be done with a water cooled tig welder and not all "welders" have one.

#6

Hello;

Major bummer, however, one good thing is that it looks like it has at least 4 threads in it, if so, one option is to flatten it and use a bottoming tap or cut a tap off and thread the hole as deeply as you can. Use a grade 8 bolt and measure the exact length you need then shorten the bolt so it has around 1 turn before it is fully bottomed out. Don’t taper the end of the bolt after you shorten it.

Bolt it on with the mount and spacer and proper torque to make sure the boss won’t crack. If it holds then install it like that and put a chain or something on that side mounted to a front cylinder head boss, then to the frame etc., with just a little play in it so when the engine is under heavy load, the chain will take a lot of the load instead of that boss.

Also, if you are considering using urethane mounts I wouldn’t do that with that mount on that side anyway, however, a urethane mount on the other side will help to reduce side movement of the engine which will also help.

As mentioned, a very good cast iron welder can weld a boss on that, but even if you hand him the boss, it still might cost close to $200.00.

It should also be done with a water cooled tig welder and not all "welders" have one.

Major bummer, however, one good thing is that it looks like it has at least 4 threads in it, if so, one option is to flatten it and use a bottoming tap or cut a tap off and thread the hole as deeply as you can. Use a grade 8 bolt and measure the exact length you need then shorten the bolt so it has around 1 turn before it is fully bottomed out. Don’t taper the end of the bolt after you shorten it.

Bolt it on with the mount and spacer and proper torque to make sure the boss won’t crack. If it holds then install it like that and put a chain or something on that side mounted to a front cylinder head boss, then to the frame etc., with just a little play in it so when the engine is under heavy load, the chain will take a lot of the load instead of that boss.

Also, if you are considering using urethane mounts I wouldn’t do that with that mount on that side anyway, however, a urethane mount on the other side will help to reduce side movement of the engine which will also help.

As mentioned, a very good cast iron welder can weld a boss on that, but even if you hand him the boss, it still might cost close to $200.00.

It should also be done with a water cooled tig welder and not all "welders" have one.

But anywho guys. Small update. The salvage yard is going to honor a 30 day warranty past 30 days. Dropped the motor off at my buddy's shop yesterday and they should have the "new" motor delivered around 1-2 o'clock today

I'm good with that. Thanks for the help guys. Oh, and it turns out the explorer was in a very bad wreck involving a front end impact. Have a good one, and keep on wrenchin!

I'm good with that. Thanks for the help guys. Oh, and it turns out the explorer was in a very bad wreck involving a front end impact. Have a good one, and keep on wrenchin!

#7

Thanks for the info man. I do have urethane mounts for each side. I'm not even sure the company that makes my mounts even sells non-urethane mounts for the custom mounts they make. But geez. 200 bucks!? Thats almost what I have in the motor. haha. Also, I'm not crazy about the chains dangling all over the place. That sounds like it would look kinda trashy.

But anywho guys. Small update. The salvage yard is going to honor a 30 day warranty past 30 days. Dropped the motor off at my buddy's shop yesterday and they should have the "new" motor delivered around 1-2 o'clock today I'm good with that. Thanks for the help guys. Oh, and it turns out the explorer was in a very bad wreck involving a front end impact. Have a good one, and keep on wrenchin!

I'm good with that. Thanks for the help guys. Oh, and it turns out the explorer was in a very bad wreck involving a front end impact. Have a good one, and keep on wrenchin!

But anywho guys. Small update. The salvage yard is going to honor a 30 day warranty past 30 days. Dropped the motor off at my buddy's shop yesterday and they should have the "new" motor delivered around 1-2 o'clock today

I'm good with that. Thanks for the help guys. Oh, and it turns out the explorer was in a very bad wreck involving a front end impact. Have a good one, and keep on wrenchin!

I'm good with that. Thanks for the help guys. Oh, and it turns out the explorer was in a very bad wreck involving a front end impact. Have a good one, and keep on wrenchin!

#9

Thanks for the info man. But geez. 200 bucks!? Thats almost what I have in the motor. haha. Also, I'm not crazy about the chains dangling all over the place. That sounds like it would look kinda trashy. The salvage yard is going to honor a 30 day warranty past 30 days.

Yeah it's an art and very time consuming to weld something like that properly on cast iron. Good cast iron welders are few and far apart. Part of the reason is that people don't want to pay what it costs to get a cast iron part welded properly which is understandable. As you implied, why pay close to $200.00 to weld it when you can simply buy another complete engine for less.

Also, I agree with you that a chain would look a bit trashy, however, if you absolutely had to weld it, it will look a lot better than your engine possibly putting a big dent in your hood if it broke, lol.

.

Last edited by barnett468; 10-21-2014 at 09:38 AM.

#10

Yep

Yeah, it might cost me more in gas than a new block to come get it. haha. Thanks though.

Yep. I'm very satisfied they were able to work with me. I agree, welding cast is not as simple as most people think (that was me at first).

Update to y'all though, a "new" 98 Explorer 5.0 is sitting at my buddies shop right now. He called me around lunch time. Also said this one has a lot more stuff on it, and almost nothing is missing. Probably try and pick it up tomorrow.

No prob, you're welcome but I'm glad they warranteed it for you. An unrepaired block is obviously way better.

Yeah it's an art and very time consuming to weld something like that properly on cast iron. Good cast iron welders are few and far apart. Part of the reason is that people don't want to pay what it costs to get a cast iron part welded properly which is understandable. As you implied, why pay close to $200.00 to weld it when you can simply buy another complete engine for less.

Also, I agree with you that a chain would look a bit trashy, however, if you absolutely had to weld it, it will look a lot better than your engine possibly putting a big dent in your hood if it broke, lol.

.

Yeah it's an art and very time consuming to weld something like that properly on cast iron. Good cast iron welders are few and far apart. Part of the reason is that people don't want to pay what it costs to get a cast iron part welded properly which is understandable. As you implied, why pay close to $200.00 to weld it when you can simply buy another complete engine for less.

Also, I agree with you that a chain would look a bit trashy, however, if you absolutely had to weld it, it will look a lot better than your engine possibly putting a big dent in your hood if it broke, lol.

.

Update to y'all though, a "new" 98 Explorer 5.0 is sitting at my buddies shop right now. He called me around lunch time. Also said this one has a lot more stuff on it, and almost nothing is missing. Probably try and pick it up tomorrow.