quick q on the studs that hold the carb down

#1

last little bit i still gotta do on my 2v->4v swap is actually bolting the carb down to the intake and while i thought this would be the easiest part it is becoming a pain.

the carb spacer i got came with studs but they are just a wee bit to short and the nuts dont wanna hold on to the stud...nearly chopped my finger off when trying to tighten one down and it let go and my hand went flying into the shock tower....owww.

i tried some 2" bolts i got but but my problem is this.

Holley says to torque the nuts down with 60-80lb ft. i tried this with the bolts and literally snapped the bolt in half around 45-50lb. This amount of torque seems.....excessive seeing that the intake manifold bolts are only 20-22lb ft. even using studs and a nut this seems excessive. Lastly....i thought the intake manifold bolts torque was higher and they seem.....not loose but i feel like they should be tightened down more. any problems that my arise if i do this?

Thanks

the carb spacer i got came with studs but they are just a wee bit to short and the nuts dont wanna hold on to the stud...nearly chopped my finger off when trying to tighten one down and it let go and my hand went flying into the shock tower....owww.

i tried some 2" bolts i got but but my problem is this.

Holley says to torque the nuts down with 60-80lb ft. i tried this with the bolts and literally snapped the bolt in half around 45-50lb. This amount of torque seems.....excessive seeing that the intake manifold bolts are only 20-22lb ft. even using studs and a nut this seems excessive. Lastly....i thought the intake manifold bolts torque was higher and they seem.....not loose but i feel like they should be tightened down more. any problems that my arise if i do this?

Thanks

#2

I have never tightened my carb down using a torque wrench. That does seem like an excessive amount there. You shouldn't be reefing on it enough that you are going to slam your knuckles into the shock tower. You will likely break off or strip out a thread. I have always tightened hand tight drove it a few times and then checked it again to make sure nothing loosened. I am especially paranoid about aluminum just because i hate striping it and having to helicoil.

#5

Edit: Nice one Gun Jam.

I have the factory manual and thats about what it says for the cylinder heads :O

On stock '66 intake manifolds, it recommends 20-22 ft lbs, so I doubt even that much is needed with the carb. I took my carb off the other day and it required (and I'm estimating) 10 ft lbs max. But at least this is something that you can check periodically to see how tight they are.

I have the factory manual and thats about what it says for the cylinder heads :O

On stock '66 intake manifolds, it recommends 20-22 ft lbs, so I doubt even that much is needed with the carb. I took my carb off the other day and it required (and I'm estimating) 10 ft lbs max. But at least this is something that you can check periodically to see how tight they are.

#6

60 to 80 INCH POUNDS????????

60 to 80 FOOT POUNDS WILL destroy your carburator....

It will either break the ears off or it will warp the living **** out of the carb base.

I was tripping when you said that you were torquing down tight enough to hit your hand...

Damn...

<<edit - - Seeing as you already got those things pretty tight in you attempt, without breaking the ears, (whew). >>

<<edit 2 - - VERIFIED 60 to 80 INCH POUNDS

You might want to run a straight edge across the carb base...

60 to 80 FOOT POUNDS WILL destroy your carburator....

It will either break the ears off or it will warp the living **** out of the carb base.

I was tripping when you said that you were torquing down tight enough to hit your hand...

Damn...

<<edit - - Seeing as you already got those things pretty tight in you attempt, without breaking the ears, (whew). >>

<<edit 2 - - VERIFIED 60 to 80 INCH POUNDS

You might want to run a straight edge across the carb base...

Last edited by JMD; 06-30-2009 at 02:34 PM. Reason: VERIFIED 60 to 80 INCH POUNDS

#7

Carb bolts would be torqued with inch pounds, not 60-80 foot pounds. A simple reference here would be the strength to make a fist. Put your wrench on the nut/bolt in question with your palm on a solid surface a short distance from the wrench and fingers stretched out and reaching around a 6 inch long wrench. Use 2 or 3 fingers to grab the wrench and clench the wrench towards your palm as if making a fist. The strength it takes to make a firm fist will get you in the ballpark for proper torque needed here. Is this a little bit "out there"? Yep, but it's the best I can come up with at the moment to explain a small amount of torque.  It's a little more than valve covers - a lot less than intake manifold bolts...

It's a little more than valve covers - a lot less than intake manifold bolts...

#8

uhhhhhhhh .. but damn it anyway if they wrote inlbs. easily overlooked

i never torqued them either and snug is fine.

i hope you didn't warp the carb

as for the intake bolts. the 22 is fine, but you have to go around it again and again and agin. when you tighten one screw the intake settles and anothe gets loose.

so best idea is to get around in the torque sequence with 8footpunds and only when they're all at 8 footpounds do it again with 15 until you reach 22.

this takes forever and your back will complain but it's the safest way to make sure the intake is flat and not warped

i never torqued them either and snug is fine.

i hope you didn't warp the carb

as for the intake bolts. the 22 is fine, but you have to go around it again and again and agin. when you tighten one screw the intake settles and anothe gets loose.

so best idea is to get around in the torque sequence with 8footpunds and only when they're all at 8 footpounds do it again with 15 until you reach 22.

this takes forever and your back will complain but it's the safest way to make sure the intake is flat and not warped

#9

ya i re read the manual and its typoed cuz it does say "lb ft".

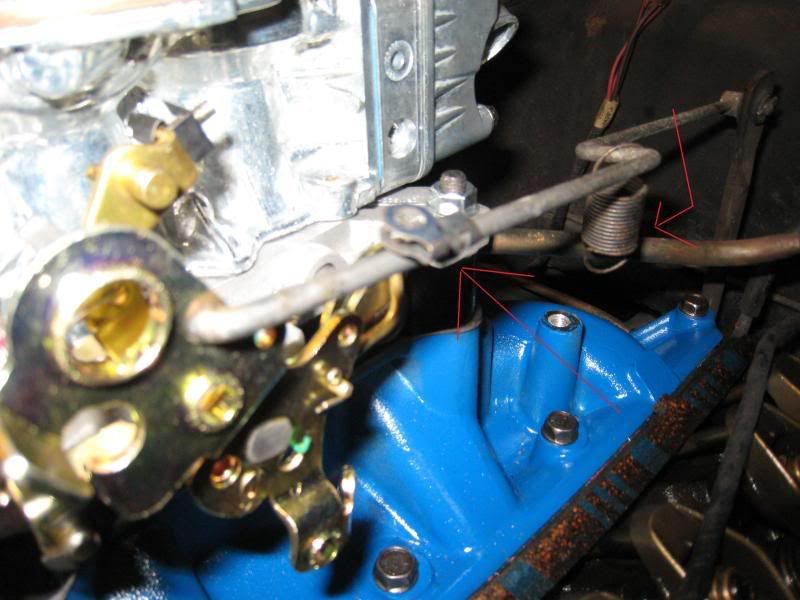

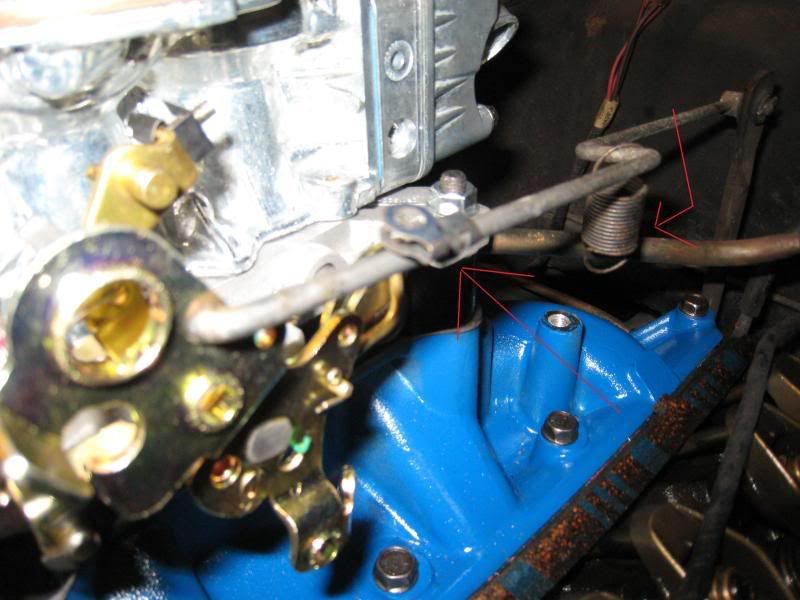

also one last thing. how exactly do you hook up the throttle. the manual is a little vague ie: "Reconnect the throttle and transmission kickdown linkage and throttle return spring (Holley P/N 20-89)" with not a single picture of it connected.

ive roamed the web a bit to no avail trying to find a pic of a 289 hooked up. this is what i have right now. the clip and spring were on the original autolite 2100. i know that clip is suppose to hold the throttle in place but i have no idea where to connect the spring up to. its approximately hanging where it was when attached to the 2100. do i need to get this other holley part? i got a couple more springs in the original kit that dont seem to go anywhere else

thanks for the help

edit....ya i checked the underside of the carb, its fine.....as much as it pissed me off at the moment im glad those bolts snapped

also one last thing. how exactly do you hook up the throttle. the manual is a little vague ie: "Reconnect the throttle and transmission kickdown linkage and throttle return spring (Holley P/N 20-89)" with not a single picture of it connected.

ive roamed the web a bit to no avail trying to find a pic of a 289 hooked up. this is what i have right now. the clip and spring were on the original autolite 2100. i know that clip is suppose to hold the throttle in place but i have no idea where to connect the spring up to. its approximately hanging where it was when attached to the 2100. do i need to get this other holley part? i got a couple more springs in the original kit that dont seem to go anywhere else

thanks for the help

edit....ya i checked the underside of the carb, its fine.....as much as it pissed me off at the moment im glad those bolts snapped

Last edited by longlive289s; 06-30-2009 at 02:55 PM.

#10

uhhhhhhhh .. but damn it anyway if they wrote inlbs. easily overlooked

i never torqued them either and snug is fine.

i hope you didn't warp the carb

as for the intake bolts. the 22 is fine, but you have to go around it again and again and again. when you tighten one screw the intake settles and anothe gets loose.

so best idea is to get around in the torque sequence with 8footpunds and only when they're all at 8 footpounds do it again with 15 until you reach 22.

this takes forever and your back will complain but it's the safest way to make sure the intake is flat and not warped

i never torqued them either and snug is fine.

i hope you didn't warp the carb

as for the intake bolts. the 22 is fine, but you have to go around it again and again and again. when you tighten one screw the intake settles and anothe gets loose.

so best idea is to get around in the torque sequence with 8footpunds and only when they're all at 8 footpounds do it again with 15 until you reach 22.

this takes forever and your back will complain but it's the safest way to make sure the intake is flat and not warped

A very good point about the over and over for the intake, another easily overlooked detail of proper assembley...