Home Made Adjustable Export Brace/Monte Carlo Bar

#1

I posted this on my car build thread but figured more people would like to see it or could benefit from it by making a thread for it with more detail. Enjoy.

Adjustable Monte Carlo Bar and Export Brace

WARNING: No fancy, super light weight, "trick" billet aluminum, or CNC or laser cut parts here folks.

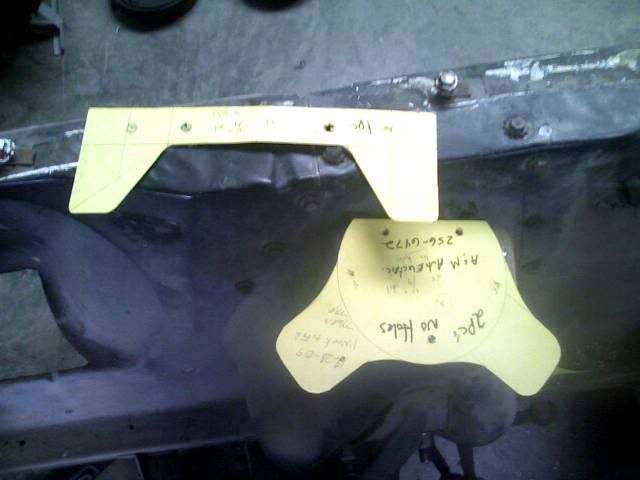

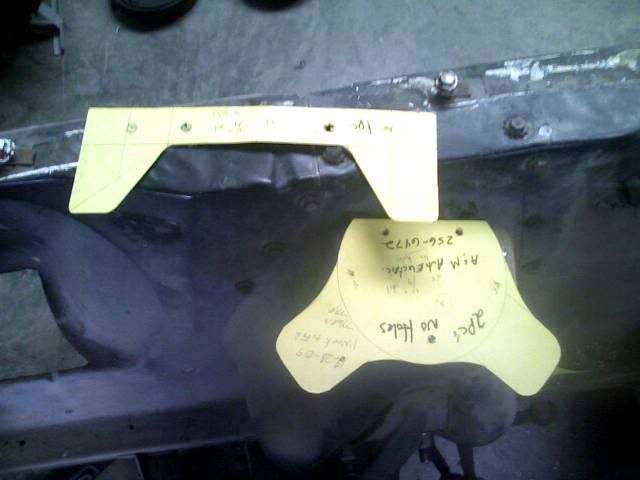

Made some cardboard templates and dropped them off at a friend's shop so that he could cut them for me with his plasma cutter. The goal was to make brackets that were not too over the top in design and allowed me to mount both the export brace links and monte carlo bar to the shock towers.

I measured the length between the firewall mounting holes and added a couple of inches to each side. I believe the final length was 12" and made two tabs for the rod ends to mount to.

I started with a circle for the shock tower bracket then added tabs for the export links and monte carlo links. This is what I ended up with.

Had a friend trace these onto some 1/4" steel plate and cut them out with his plasma cutter. I forgot to tell him to cut out the holes for the shocks so I will have to take them back later for that.

I chose to drill the holes myself one by one to ensure they would all line up. Started out with one hole from the template and used a transfer punch to mark it for the drill press.

I started out with a step drill and drilled up to 1/4" diameter hole then changed out to a 5/16" drill to a 3/8" drill.

I used the shock tower caps to locate the other holes but dropping a 3/8" bolt in the previously drilled hole and once again using a transfer punch to mark the next hole and after drilling the second hole, repeated the process again to mark the third hole.

Using a similar process as the shock tower brackets, I drilled one hole at a time on the firewall bracket, mounted it, marked the next hole, drilled it, re-mounted, etc.

Mounted up the shock tower bracket as well to start taking measurements and deciding where to drill holes for the rod ends.

After deciding where to drill holes for the rod ends, I drilled them going from a step drill to 5/16" to 3/8" to 1/2" and finally to 5/8" which is a very expensive drill bit.

I mounted up the rod ends and took measurements between the tube adapters and decided on a 10.5" length tube.

Used some scrap tubing I had laying around to mock stuff up before I cut up some perfectly good mild steel.

First I used some spare hardware I had laying around to mock up the first link. Then I decided that looking for matching spare hardware in a "box-o-****" is a pain in the ***, I took my *** down to the hardware store and picked up some 5/8" hardware. Allen head bolts and nylon locking nuts.

Then the other side

Both. I do have some contact between the rod ends and the brackets because the misalignment is a little too much but some tapered cone steel spacers should take care of this problem very easily. On order.

Since I have not drilled holes yet for the monte carlo bar, I used c-clamps top hold the rod ends in place and took a measurement: 27". Cut it and mocked it up. Won't be bolting it in until the motor goes in to make sure I clear the distributor.

Will be updating this post as I take care of the details.

Fred

Adjustable Monte Carlo Bar and Export Brace

WARNING: No fancy, super light weight, "trick" billet aluminum, or CNC or laser cut parts here folks.

Made some cardboard templates and dropped them off at a friend's shop so that he could cut them for me with his plasma cutter. The goal was to make brackets that were not too over the top in design and allowed me to mount both the export brace links and monte carlo bar to the shock towers.

I measured the length between the firewall mounting holes and added a couple of inches to each side. I believe the final length was 12" and made two tabs for the rod ends to mount to.

I started with a circle for the shock tower bracket then added tabs for the export links and monte carlo links. This is what I ended up with.

Had a friend trace these onto some 1/4" steel plate and cut them out with his plasma cutter. I forgot to tell him to cut out the holes for the shocks so I will have to take them back later for that.

I chose to drill the holes myself one by one to ensure they would all line up. Started out with one hole from the template and used a transfer punch to mark it for the drill press.

I started out with a step drill and drilled up to 1/4" diameter hole then changed out to a 5/16" drill to a 3/8" drill.

I used the shock tower caps to locate the other holes but dropping a 3/8" bolt in the previously drilled hole and once again using a transfer punch to mark the next hole and after drilling the second hole, repeated the process again to mark the third hole.

Using a similar process as the shock tower brackets, I drilled one hole at a time on the firewall bracket, mounted it, marked the next hole, drilled it, re-mounted, etc.

Mounted up the shock tower bracket as well to start taking measurements and deciding where to drill holes for the rod ends.

After deciding where to drill holes for the rod ends, I drilled them going from a step drill to 5/16" to 3/8" to 1/2" and finally to 5/8" which is a very expensive drill bit.

I mounted up the rod ends and took measurements between the tube adapters and decided on a 10.5" length tube.

Used some scrap tubing I had laying around to mock stuff up before I cut up some perfectly good mild steel.

First I used some spare hardware I had laying around to mock up the first link. Then I decided that looking for matching spare hardware in a "box-o-****" is a pain in the ***, I took my *** down to the hardware store and picked up some 5/8" hardware. Allen head bolts and nylon locking nuts.

Then the other side

Both. I do have some contact between the rod ends and the brackets because the misalignment is a little too much but some tapered cone steel spacers should take care of this problem very easily. On order.

Since I have not drilled holes yet for the monte carlo bar, I used c-clamps top hold the rod ends in place and took a measurement: 27". Cut it and mocked it up. Won't be bolting it in until the motor goes in to make sure I clear the distributor.

Will be updating this post as I take care of the details.

Fred

#3

Haven't done that quite yet. I'm holding off drilling holes for the monte carlo bar until the motor goes in. If need be, I also have some shock mount tabs that I can use to raise the bar a bit. I need to order motor mounts and drop the motor in soon.

#5

Nice DIY job, did you consider making the firewall mount piece out of angle iron so you could bolt through the firewall so all the pressure isn't on those 4 bolts through the crimped horizontal cowl piece? Like they did on the Shelby's?

Just curious.

Jon

Just curious.

Jon

#6

Actually yes. I will be doing that this coming week. I need to run down and grab some angle iron and flat stock. I was also thinking of adding another flat strip across the top of the firewall the the bracket is already bolted. Will be updating this coming week.

#8

No plans for production. LOL I'll leave that up to the guys who do this for a living. Powdercoating will take place as soon as I get my new compressor as my old one took a crap on me last November.

Thread

Thread Starter

Forum

Replies

Last Post