What the eff?!

#1

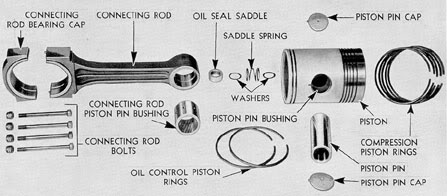

So I bought some piston rings from total seal, filed them, installed them and two of them snapped during installation....wtf?! Will total seal replace bad product? I used the proper installation tool as well!

#2

It doesn't hurt to try, they may be good merchants and stand behind their product. All they can say is no, most companies will send you a new set and examine the set that was damaged to figure out if negligence was evident. On a set of piston rings I don't know how you would come to a conclusion if you broke them on purpose, but have at it!

#3

Two out of 24 isn't bad, I have broken more than that on some engines. It is one of those "knack" kind of things and sometimes even after 50+ years of rebuilding engines I still break one now and then.

What kind of tool did you use?

This kind and its ilk are ring breakers:

This, oddly enough from Harbor Freight, which provides more support of the ring's perimeter works much better:

What kind of tool did you use?

This kind and its ilk are ring breakers:

This, oddly enough from Harbor Freight, which provides more support of the ring's perimeter works much better:

#5

#6

So cliffy, they are honoring the rings and replacing. I just realized that the second ring is iron lol is there a trick to it like heating them to make them more maliable? I'm so scared about breaking more lol.

#8

^Yeah, you probably have the "knack" by now. A problem with not using a tool and "spiraling" them one is that you can twist the ring and cause it to bind in the groove--those experienced with installing them by hand (as I have done many times) know to avoid this. The tool has a learning curve too and does makes it easier once you learn to use it.

Make sure to open the ring only as much as is 100% needed to slip it down into the proper groove--no more. I have an old K-D Tools installer of the "non-fancy" type that has a thumb screw you can set to block spreading the ring anymore than necessary...

Total Seal knows they break sometimes, that's why they stand behind them...

Make sure to open the ring only as much as is 100% needed to slip it down into the proper groove--no more. I have an old K-D Tools installer of the "non-fancy" type that has a thumb screw you can set to block spreading the ring anymore than necessary...

Total Seal knows they break sometimes, that's why they stand behind them...

#9

Motor man, I'm a machinist and like cliffy said I know that is not the best thing to do. Cliffy, I thought I had the knack for it lol. But the motors I work on at work are a bit bigger lol