Cool it! Upgrading the Kenne Bell Intercooler

#22

after loooots of searching and calling I found out how many LPM did the GT500/ the Lightning pump make.

http://www.siliconeintakes.com/produ...oducts_id=1001

(This information is directly from Bosch. Unit conversion shows that this pump flows 317 GPH; any seller who advertises differently is incorrect.)

http://rb-aa.bosch.com/boaaemocs/Pro...13&prod_id=510

it's make 317 GPH / 60 = 5.28 GPM (5.28GPM=19.9LPM) and KB (22.5 LPM which is 5.9 GPM) KB flows better so no need to change it . however, the GT500/ the Lightning pump has bigger dimension which is also not good cuz you gonna need to fabricate the bracket .

Bosch however, have another bigger pump but it's only 23.3LPM so it's not that much "KB 22.5 LPM" . on the other hand , Meziere have (20 GPM = 75.7 LPM) DAMN!!! I think it's too much for intercooler pump except if you run one of those ice boxes which mounted in the trunk.

http://www.siliconeintakes.com/produ...oducts_id=1001

(This information is directly from Bosch. Unit conversion shows that this pump flows 317 GPH; any seller who advertises differently is incorrect.)

http://rb-aa.bosch.com/boaaemocs/Pro...13&prod_id=510

it's make 317 GPH / 60 = 5.28 GPM (5.28GPM=19.9LPM) and KB (22.5 LPM which is 5.9 GPM) KB flows better so no need to change it . however, the GT500/ the Lightning pump has bigger dimension which is also not good cuz you gonna need to fabricate the bracket .

Bosch however, have another bigger pump but it's only 23.3LPM so it's not that much "KB 22.5 LPM" . on the other hand , Meziere have (20 GPM = 75.7 LPM) DAMN!!! I think it's too much for intercooler pump except if you run one of those ice boxes which mounted in the trunk.

Last edited by unicorn; 03-06-2012 at 01:58 PM.

#23

LPM GPH I always get that mixed up. I run the 55 Meziere as two friends of mine there is no such thing as too much water flow.

KB has the more horrible intercooler setup of any manufacturer I have seen. I run -12 fittings and 3/4" lines throughout my entire system. KB feeds ice cold faucet water into their motors on the dyno and tells you their stuff runs cool sorry that's BS. Start spinning a KB up at part throttle and it will boil water just going around the block. Works great if you only go wide open throttle all the time.

KB has the more horrible intercooler setup of any manufacturer I have seen. I run -12 fittings and 3/4" lines throughout my entire system. KB feeds ice cold faucet water into their motors on the dyno and tells you their stuff runs cool sorry that's BS. Start spinning a KB up at part throttle and it will boil water just going around the block. Works great if you only go wide open throttle all the time.

Last edited by 908ssp; 03-07-2012 at 12:11 AM.

#25

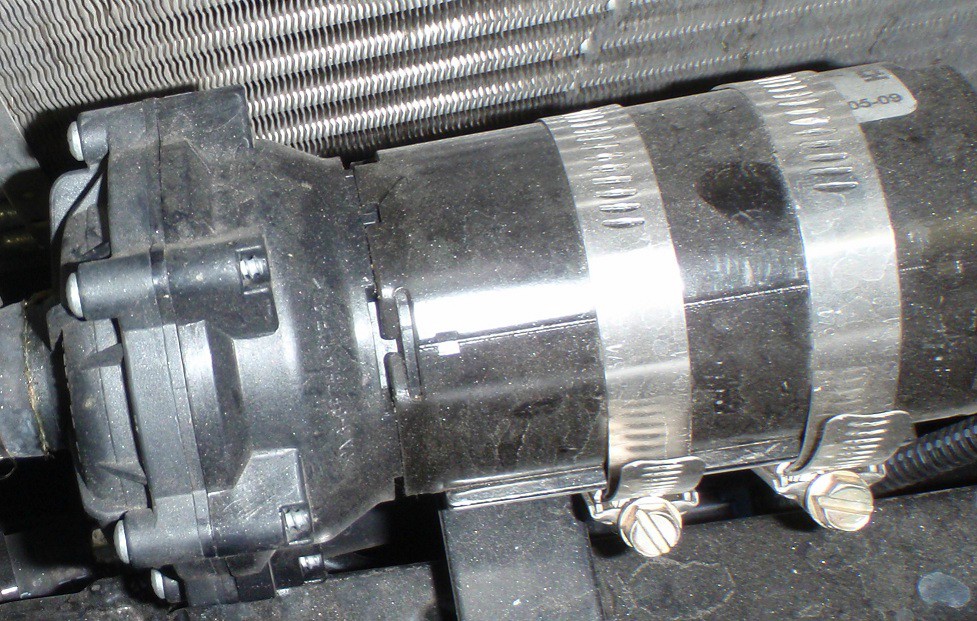

I checked today my KB intercooler pump and guess what ????

KB are using (the late kits as they said) the same GT500/lightning ford pump which has 19.98 LPM not 22.5 LPM flow as the said :roflmao:. BOSCH pump (part # 392 022 002)

you can see it on the pics (the date too) , but I couldn't reach to the other side to show the whole part# , my cam was too big to fit there (that what she said :naughty1: ) . I have my friend GT500 pump out there but I was in a hurry so I forgot to take some photos comparing between them to make sure to you guys both are the same , I can take some if you guys want

Shot at 2012-03-07

KB are using (the late kits as they said) the same GT500/lightning ford pump which has 19.98 LPM not 22.5 LPM flow as the said :roflmao:. BOSCH pump (part # 392 022 002)

you can see it on the pics (the date too) , but I couldn't reach to the other side to show the whole part# , my cam was too big to fit there (that what she said :naughty1: ) . I have my friend GT500 pump out there but I was in a hurry so I forgot to take some photos comparing between them to make sure to you guys both are the same , I can take some if you guys want

Shot at 2012-03-07

#26

I too have heard that old wives tail spread for ages. It ain't so. The water will always pickup heat the only thing that maters is the temperature of the water and temperature of the air passing through the cooler. The greater the differential of temperature the more heat will be transferred. Plus the intercooler is very restrictive especially on the KB with those tiny fittings and street elbows.

#28

If you've ever datalogged or monitored your IAT during a track or hard street run, you'd see it peak before taking off or shortly thereafter, then dropping down a little as you accelerate and pick up speed, because of the increase in air flow over the h/e I would imagine, even with higher-revs of the engine (at least that's what I've seen).

#30

If you've ever datalogged or monitored your IAT during a track or hard street run, you'd see it peak before taking off or shortly thereafter, then dropping down a little as you accelerate and pick up speed, because of the increase in air flow over the h/e I would imagine, even with higher-revs of the engine (at least that's what I've seen).

Part of what is happening is an issue with screw blowers. They tend to run hotter when working below their efficiency level. A screw blower compresses the air in the screw compressing the air creates heat. The bypass valve relieves the pressure so that the work done by the screws while tooling around is wasted and has to be disposed of by the intercooler/heat exchanger. That heated air from the bypass valve is then allowed to reenter the screws and is heated again. So that normal part throttle driving is constantly building heat in the water. Now when you get on the gas hard the bypass closes the screw blower then starts pushing cold fresh air from the intake into the engine and the IA temperatures drop. So for full throttle runs a screw blower looks like it runs cooler. A roots blower gets hotter on full throttle but runs cooler at partial throttle. For around town driving a roots blower makes more sense for drag racing a screw blower makes more sense. That is why you find roots or improved roots type blowers on cars designed to be driven on a day to day basis in traffic for tens of thousands of miles.

There are things that can be done to improve the cooling of a screw blower. The larger the blower the slower it has to turn for a given hp the cooler it will run. The larger the intake elbow, intake tube and filter are the cooler it will run because you can turn the blower slower. The intercooler is pretty limited in size but seeing that the heated air is forced through the core it does a fairly good job. Making the heat exchanger as large as possible and pumping the water through as fast as possible helps. Making sure all the air entering the front of the car goes through the heat exchanger and not around it is important and often over looked. I built a duct for KB which already had an extra large heat exchanger and dropped IATs 15 degrees.

Last edited by 908ssp; 03-07-2012 at 10:39 PM.