Ford Mustang V6 1994-2004: Engine Noise Diagnostic Guide

Clicking and clattering engines are not happy campers, yet they regularly continue to be operated until they meet their demise. A noisy engine is trying to tell you something important. Will you take time and listen?

This article applies to the V6 Ford Mustang (1994-2004).

Any type of abnormal engine noise can be a cause for concern. While modern engines are generally quite reliable and are now easily able to eclipse 100,000 miles, problems occasionally crop and and lead to various engine noises. Some noises are perfectly normal with higher mileage engines, but it is important to take note of the frequency, duration, and type of noise that is occurring within your engine. In most cases, early detection of an internal engine noise can minimize repair costs compared to a noise that is left unchecked and later causes major engine damage. This article will provide an overview of common engine noises for the 1994 to 2004 V6 Mustang models.

Materials Needed

- Mechanic's stethoscope

- 1/4 length of vinyl hose

- Metric and American sockets/wrenches

- Ratchet and extensions

- Floor jack and jack stands

Pro Tip

Before attempting to diagnose an internal engine noise, inspect all engine driven accessories to ensure they are not the source of the problem.

Step 1 – Check for exhaust leaks

Exhaust leaks are one of the most common engine noises that arise, and are often misinterpreted as a more serious internal engine noise. Exhaust leaks around the exhaust manifolds tend to make a ticking or popping noise. These noises will typically cease once the engine has warmed up and the exhaust manifolds expand to seal off the leak; however, larger leaks will continue to make noise after the engine reaches operating temperature. A strong exhaust odor often accompanies an exhaust leak and may intrude into the cabin. Exhaust leaks can also occur further downstream in the exhaust system at a collector flange or muffler. In any case, probing the exhaust system with a mechanic's stethoscope or length of 1/4" hose while listening for exhaust pulsations can allow for quick identification of a leaking exhaust. Generally, tightening exhaust bolts or replacing exhaust gaskets will cure the leak and eliminate any unwanted noises.

Step 2 – Check valve train

The valve train is responsible for the flow of air/fuel mixture and exhaust gases into and out of the cylinders. The valve train includes the camshaft, lifters, push rods, rocker arms, valves and springs. Since the camshaft operates at 1/2 the speed of the crankshaft, any engine noise that seems to be occurring at half of the engine speed can usually be traced to the valve train. More often than not, the valve train will make a ticking noise when something is not quite right (typically five to six ticks when idling at 700 rpm). The valve train is said to be the weakest area on any type of engine, and most catastrophic engine failures originate from a valve train issue. Fortunately, the valve covers are easily accessible on the Mustang and can easily be removed for a quick inspection of the rocker arms, push rods, valve springs, and valve stems to aid in diagnosis. With the engine running, a stethoscope and small piece of hose can easily help you to identify the noisy valve train component(s). Listed below are a few general problems that can cause a valve train noise.

- Valve train ticking that occurs during start-up but disappears after a few minutes with the engine running is completely normal. This usually occurs because engine oil has drained out of the hydraulic lifters while it was off and they must fill back up with oil after the engine runs a bit.

- Valve train noise that increases proportionately to the engine speed is often a valve lash (rocker arm to valve stem clearance) issue. Excessive clearance can be caused by a loose or worm rocker arm, a bent or damaged push rod, or an oil supply issue stemming from a lifter or push rod. Removing the valve cover and checking valve lash can usually identify the cause of the noise.

- The amount of engine oil can affect the proper operation of the lifters and cause excessive noise. Typically associated with a ticking or clicking noise that occurs at higher engine speeds is an overfull crankcase with too much oil, which can cause aeration of the oil that prevents the lifters from operating correctly. Similarly, too low of an engine oil level or excessively dirty oil can can allow for intermittent clicking noises.

Pro Tip

Do not shrug off a valve train noise! An engine operating with a faulty component in the valve train is susceptible to dropping a valve and wiping out an entire engine. While removal of the cylinder head may be required to fix the problem, it will be a lot cheaper than replacing or completely rebuilding the engine.

Step 3 – Check pistons and connecting rods

As an engine accumulates mileage, parts tend to wear and tolerances loosen up leading to various noises. If the noise is not coming from the topside of the engine and is occurring at the same speed the engine is turning, it may be coming from a piston or connecting rod.

Piston Slap

Piston slap will usually make a consistent, metallic clatter that some say sounds like a muffled bell ringing. This is often caused by a worn piston rocking in the cylinder bore. Piston slap can go away after the engine heats up and the piston expands to take up excessive clearance in the cylinder bore, or as the engine is accelerated. Engines with minimal piston slap at start-up have lasted many miles; however, excessive slap that is always present will require a new piston and/or the cylinder re-bored.

Piston Pin or Wrist Pin Slap

Piston pin or wrist pin slap is caused by excessive wear in either the small end of the connecting rod or the piston pin bore. With a worn wrist pin, the piston will continue to travel in one direction as the rod is heading the other way until the slack is taken up to pull the piston back into the correct direction of travel. This "double-tap" noise, similar to valve train ticking, will usually occur at a certain rpm while the engine is under acceleration.

Connecting Rod Knock

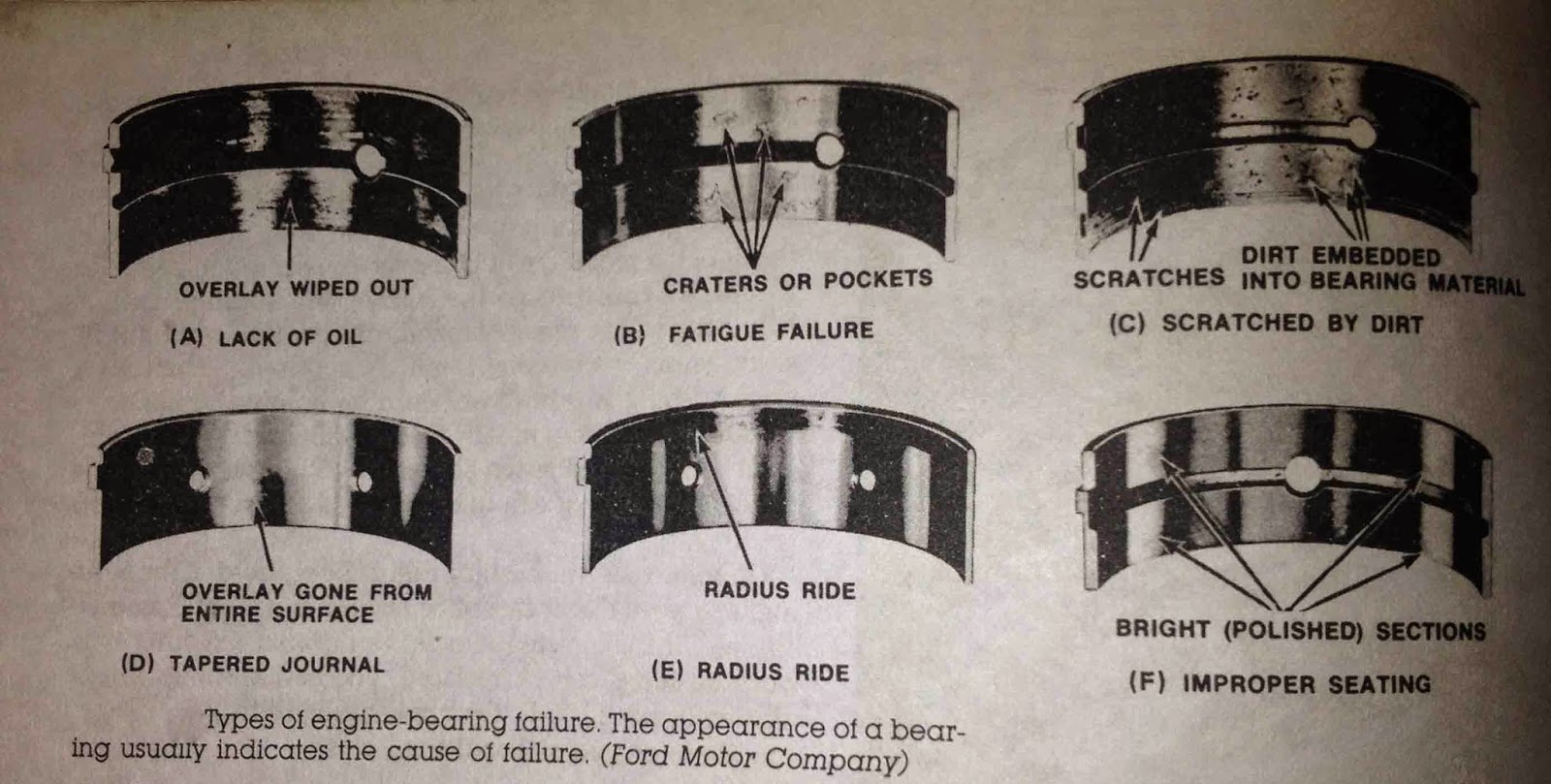

Connecting rod knock results from excessive wear in the rod bearings or the rod journal on the crankshaft. Generally, rod knock occurs while the engine is under a light load with engine speeds upwards of 2,500 rpm. As rpm increases, the knock will often become louder and increase in speed. Rod bearings and bearing to journal clearance can be inspected by removing the oil pan. If the rod journal is in good condition, new bearings can be installed fairly easily with the engine still in the car at minimal costs.

Pro Tip

Shorting out spark at each cylinder can usually help to identify which piston or rod the noise is coming from.

Step 4 – Check crankshaft

A heavy metallic knocking noise or "thud" deep within the engine can be associated with crankshaft bearing wear. The first sign of worn main bearings is lower than normal oil pressure. As the main bearings wear, tolerances increase and there is less resistance for oil to flow, reducing oil pressure. When the bearing or main journals have worn excessively, a heavy knock will be present, especially with the engine under a heavy load. Excessive crankshaft end play, or the forward and back movement of the crankshaft, will make a similar noise to main bearing wear, but occurs at irregular intervals and may be noticeable while idling. In either case, work on the bottom-end of the engine is quite in-depth and often requires removal of the engine from the car for repair.

Pro Tip

A damaged, loose, or broken flywheel/flex plate can make noises that are misinterpreted as crankshaft noise.

Related Discussions

- 2000 V6 Ticking From Engine- MustangForums.com

- Engine Noise - MustangForums.com

- V6 Engine Noise - MustangForums.com