Adjustable LCA install gone awry. . . HELP.

#1

i installed BMR LCA relocation brackets and Spohn poly/rod adjustable lower control arms today. Always takes me WAY longer than i expect. Adjusted the pinion angle when i was done and went for a test drive. All was fine except 1) the rear end kicked to the right when i downshifted quickly to 2nd and 2) several times a thud/pop came from the rear suspension as if something was moving/shifting when it is rapidly placed under load [down shifting, launching]. i followed all the directions. i put silicone grease on the poly bushings to keep them from squeaking. i didn't tighten the bolts all the way til the car was on the ground. i followed what few directions i had and those from CrazyAl on the pinion angle adjustment and from stangnet.com on the LCA install. i checked everything and have no idea where to go from here! I wasn't expecting to have any trouble with this and i'm going on a long trip in the car and autocrossing next weekend. i don't have 100% confidence that the car is safe. any helpful suggestions welcomed!!

#2

Moosestang had something to say about BMR brackets, seems some problems with them. If the bracket is not secure they could probably cause the problem you are describing.

#3

thanks Jerjan. i made sure the brackets were solid.

i forgot to mention that when shifting from 3rd to 2nd at about 3k rpms, the rear end "shifts" to the right. very unsettling and i have no idea what the deal is. i followed what little instructions Spohn and BMR provided and the stuff i got from this and other forums. any ideas?

i forgot to mention that when shifting from 3rd to 2nd at about 3k rpms, the rear end "shifts" to the right. very unsettling and i have no idea what the deal is. i followed what little instructions Spohn and BMR provided and the stuff i got from this and other forums. any ideas?

#4

I believe the torque is supposed to be about 129 lbs on the lca bolts. They are also reccomend toweld in (the relocation brackets) Make sure you have got all bolts up to torque specs. But do not over tighten. I think it is easier to put pressure on the supension while the car is on jacks and tighten the bolts from there. Mycar is lowered and its the only way to get tothe bolts very well. I assume you put the spacer in the relocation bracket. I had to cut mine to fit.

#5

It was Che brackets and I think they contributed to my rear end sitting crooked. I had to adjust my passenger side lower control arm to get it straight so one control arm is shorter than the other. If it's crooked it could cause the rear end to kick out to one side.

ORIGINAL: jerjan

Moosestang had something to say about BMR brackets, seems some problems with them. If the bracket is not secure they could probably cause the problem you are describing.

Moosestang had something to say about BMR brackets, seems some problems with them. If the bracket is not secure they could probably cause the problem you are describing.

#6

I had my Spohn combo LCAs within 1mm in length and pinion angle at -1 degree. When I went in for a front alignment I had to get a4 wheel because my rear end wasn't straight. Make sure Pinion angle is negative and be very careful placing angle finder on pinion yoke, very easy to ge it on the wrong plane and make adj incorrectly. If 0 drop use stock axel mount location (forget relocation bracket), 1-1.5" drop use BMRs upper, not lower mount holes. and use a good torque wrench. As tight as you can get it is not good enough, if you wrench or ratchet you won't hit 129fp.

#8

ORIGINAL: rlgva

I believe the torque is supposed to be about 129 lbs on the lca bolts. They are also reccomend toweld in (the relocation brackets) Make sure you have got all bolts up to torque specs. But do not over tighten. I think it is easier to put pressure on the supension while the car is on jacks and tighten the bolts from there. Mycar is lowered and its the only way to get tothe bolts very well. I assume you put the spacer in the relocation bracket. I had to cut mine to fit.

I believe the torque is supposed to be about 129 lbs on the lca bolts. They are also reccomend toweld in (the relocation brackets) Make sure you have got all bolts up to torque specs. But do not over tighten. I think it is easier to put pressure on the supension while the car is on jacks and tighten the bolts from there. Mycar is lowered and its the only way to get tothe bolts very well. I assume you put the spacer in the relocation bracket. I had to cut mine to fit.

the bolts are not one time use, butthe nuts are. locktite makes it unnecessary for new nuts, and the only ones re-used are the front ones on the LCAs. all the others are new hardware.

#9

ORIGINAL: VWILLO

I had my Spohn combo LCAs within 1mm in length and pinion angle at -1 degree.

I had my Spohn combo LCAs within 1mm in length and pinion angle at -1 degree.

The following was written by CrazyAl:

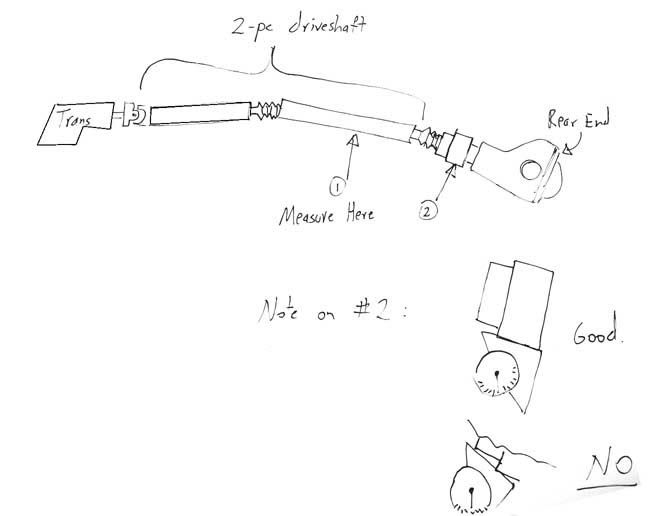

OK, here is the pinion angle setting procedure for an OEM 2-pc driveshaft. (This is NOT correct for a solid 1-pc aftermarket driveshaft)

First, lift up the car so that you can work under it. Be sure you use safe lifting procedures. Youmust have the rear suspension loaded--in other words, you need to have the tires on ramps or the rear axle tube on stands so the weight of the car is compressing the rear suspension.

It is best if the car is as level as you can get it, so if possible lift up the front to the same height as the rear. You're not going to be working on the front end, so it doesn't matter if the front suspension is loaded or not.

You are now ready to take measurements. I attached a rough sketch that shows where you are doing the measuring.

Now, use the angle gage to measure the angle of the driveshaft right next to the rear end. It doesn't really matter what this number is, just measure it and write it down. Take the measurement at the place labeled "1" on the sketch.

Move the angle gage over and measure the angle of the pinion itself. The actual pinion shaft isinside the rear end housing, so you have to take the measurement on the piniondrive flange. This isthe place makred "2" on the sketch. Make sure you are holding the gagefirmly on the wider part of the flange.Don't allow the gage to lean across the little step machined on it. (See the note on the sketch) Write this number down too.

You are interested in the difference between these two numbers. So, take the angle of the driveshaft and subtract the angle of the pinion from it.

The correct measurement will be about 3 to1.5 degrees difference, with the pinion being closer to horizontal than the driveshaft is. In other words, 0 degrees would have the measurements the same: The driveshaft and the pinion would be perfectly in line. You want the pinion to be angled down lower by about3 to 1.5 degrees. (Technically, this is called a negative angle, as in "-3 degree pinion angle", but wether or not the actual measurement is negative depends on how your angle gage is calibrated, so that is not always reliable)

If your measurement is not correct, then you need to adjust it. To do that, loosen the locknuts on your LCAs and then turn the center adjusters. Lengthening the LCAs will bring the nose of the pinion down, which will give you a larger angle difference. Be sure you have both LCAs set the same. You can either count turns and repeat the same change on both sides, or you can use a tape measure to measure the LCA lengths and keep them the same that way.

Once you've adjusted them a bit, check the angle again. Repeat adjusting and checking until the angle is where you want it. Once you've got it set, put a few drops of loctite on the adjusting nuts and tighten them down. Lower the car and go for a test drive.

How do you know what the proper angle is? Well, some of this is trial and error. You might have to reset it if things aren't to your liking. However, the general rule is that the more aftermarket parts you have in your rear suspension, the less the angle difference needs to be. 3.0-2.5 degrees is about right for a street car with relatively minor suspension mods. If you have a lot of aftermarket parts in the rear end (combo type UCA and LCAs+ more) then you could try 2.0 degrees instead. A full race setup might be 1.5 or even 1.0 degrees, though this would be an extreme situation: no rubber or polyanywhere in the rear suspension, reenforced frame, etc.

What is the theory behind this? Well, when you accelerate hard the whole axle assembly rotates a bit. Newton said every action has an equal and opposite reaction. Well, when the engine turns the wheels, a reaction torque is applied to the axle. On a race car with a SOLID suspension nothing much happens, but on a street car the rubber/poly bushings flex a bit and the axle housingrotates a little. You are setting it up so that when you get on the gas hard, and the axle twists a bit, THEN the driveshaft and the pinion are in perfect alignment. [end of article]

When I went in for a front alignment I had to get a4 wheel because my rear end wasn't straight. Make sure Pinion angle is negative and be very careful placing angle finder on pinion yoke, very easy to ge it on the wrong plane and make adj incorrectly.

If 0 drop use stock axel mount location (forget relocation bracket), 1-1.5" drop use BMRs upper, not lower mount holes. and use a good torque wrench. As tight as you can get it is not good enough, if you wrench or ratchet you won't hit 129fp.

thanks everybody for chiming in!!!!!!

#10

Sorry to say but the Factory Bolts are indeed one time use bolts. Go ask your Ford Dealer. And while many have reused them without issue others have had issues with them not staying tight. And you must use a Torque Wrench to properly tighten them.

Richard

Richard