Lifters keep collapsing wth is going on??

#21

Yes I was aware of the importance of pr geo. I asked both trick flow and comp how to set it up. They stated a very similar process that I followed and it yielded a result that matched what they said to look for...although it looks like the rocker sits low on the stud so i dont know.

As for preload the instructions said 1 turn of but all the techs said to run 1/2 turn after the fact..but even at 1 turn I doubt the lifter would have bottomed and how would excess preload crush that disc if it didnt bottom out the lifter?

As for PTV clearance there are no marks on the valves or piston. the engine always rolled over by hand smooth with no binding or clinking. If the valves were smacking the piston wouldn't that bend pushrods, chip valves and dent piston tops plus cause binding and a real mess?

Thanks guys!

As for preload the instructions said 1 turn of but all the techs said to run 1/2 turn after the fact..but even at 1 turn I doubt the lifter would have bottomed and how would excess preload crush that disc if it didnt bottom out the lifter?

As for PTV clearance there are no marks on the valves or piston. the engine always rolled over by hand smooth with no binding or clinking. If the valves were smacking the piston wouldn't that bend pushrods, chip valves and dent piston tops plus cause binding and a real mess?

Thanks guys!

#22

Yes I was aware of the importance of pr geo. I asked both trick flow and comp how to set it up. They stated a very similar process that I followed and it yielded a result that matched what they said to look for...although it looks like the rocker sits low on the stud so i dont know.

As for preload the instructions said 1 turn of but all the techs said to run 1/2 turn after the fact..but even at 1 turn I doubt the lifter would have bottomed and how would excess preload crush that disc if it didnt bottom out the lifter?

As for PTV clearance there are no marks on the valves or piston. the engine always rolled over by hand smooth with no binding or clinking. If the valves were smacking the piston wouldn't that bend pushrods, chip valves and dent piston tops plus cause binding and a real mess?

Thanks guys!

As for preload the instructions said 1 turn of but all the techs said to run 1/2 turn after the fact..but even at 1 turn I doubt the lifter would have bottomed and how would excess preload crush that disc if it didnt bottom out the lifter?

As for PTV clearance there are no marks on the valves or piston. the engine always rolled over by hand smooth with no binding or clinking. If the valves were smacking the piston wouldn't that bend pushrods, chip valves and dent piston tops plus cause binding and a real mess?

Thanks guys!

Yeah, one complete turn is too much, in my experiences. I couldn't see from the close-up (good shot, btw), were they link bars? I run about 1/4-1/2 turn. Considering my cams duration, that's were I make the most vac. You won't get PTVC by turning over by hand, unless extreme on the clearances. After things heat up and with any uncontrolled "bounce" that's were the "fertilizer will hit the ventilator". As you probably know it'll occur at overlap.

How long have those suspect lifters been in use? If you can prove your wear pattern, and not long, I'm surprised Comp wouldn't ask for a return and offer up a new set.

It sure does look like a defective issue.

I had the top retainer disc "pop out" of mine and they gave me a replacement.

Good Luck!

#23

They are link bar lifters. They have about 4k on them one failed at about 2500 it was replaced the other failed just now and its buddy on the same link bar had the same thing failing on it the first one failed exact as the 2nd im sure all 3 have the same issue.

Comp is taking care of me they have been quite helpful. I actually pulled the lifter apart against their recommendation because I wanted to make sure it was dirt in the check valve before I put the whole **** back together...haha nope glad I checked!!!

The heads are brand new never touched they came assembled by trick flow for use with hydraulic roller cams

the push rod is number 7770 length 6.650 with .080 wall

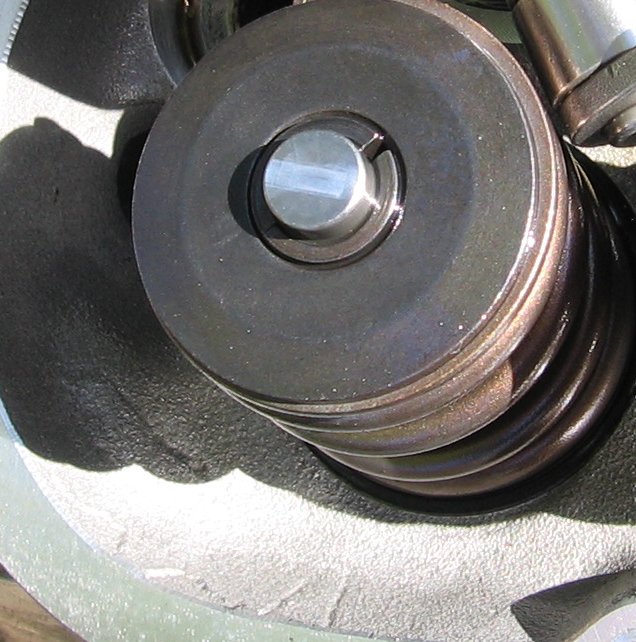

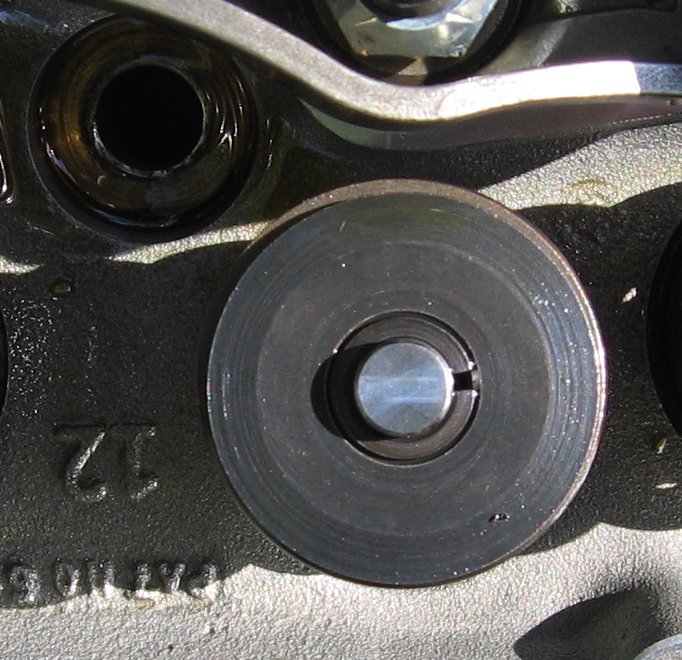

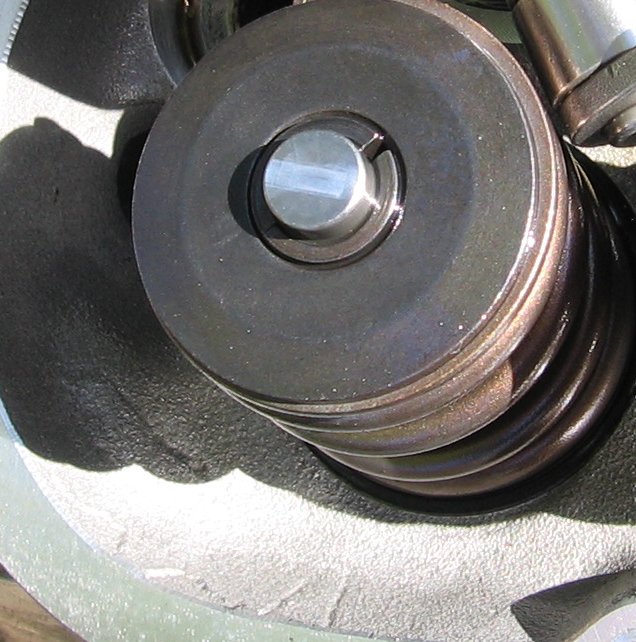

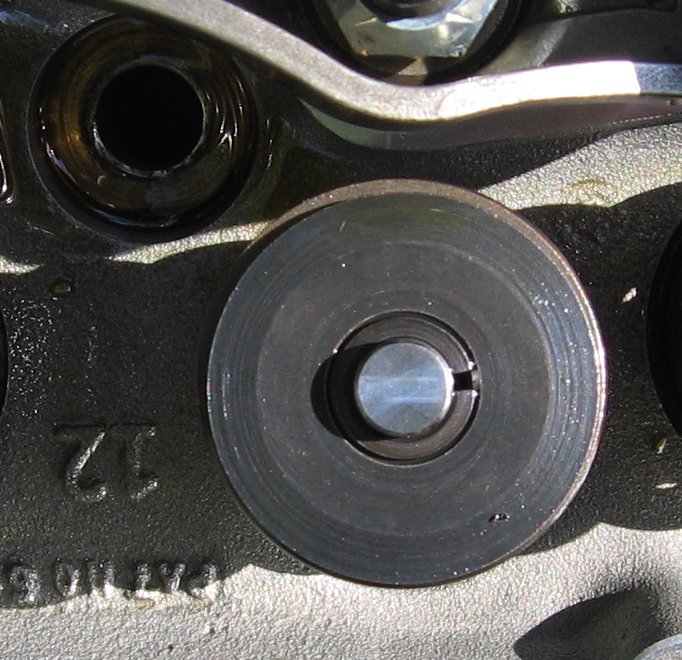

Below is the natural contact pattern left on the valve stem. 2 photos of 2 separate valves. It appears the valves have rotated slightly during their use some more than others. The cam, heads, lifters all have the same run time about 4,000 miles maybe less daily driven.

Comp is taking care of me they have been quite helpful. I actually pulled the lifter apart against their recommendation because I wanted to make sure it was dirt in the check valve before I put the whole **** back together...haha nope glad I checked!!!

The heads are brand new never touched they came assembled by trick flow for use with hydraulic roller cams

the push rod is number 7770 length 6.650 with .080 wall

Below is the natural contact pattern left on the valve stem. 2 photos of 2 separate valves. It appears the valves have rotated slightly during their use some more than others. The cam, heads, lifters all have the same run time about 4,000 miles maybe less daily driven.

#24

Well, there is nothing wrong with the P/R Geo. It looks good!

Where are you running your pre-load now? Actually, pre-load should be approx. .060-.070. It can be measured through a combination of your stud size and thread count together with your rocker ratio.

Where are you now with Comp?

Where are you running your pre-load now? Actually, pre-load should be approx. .060-.070. It can be measured through a combination of your stud size and thread count together with your rocker ratio.

Where are you now with Comp?

#25

wow I actually did something right i guess.

Preload was 1 turn I set it to 1/2, way after the fact. I don't know the thread pitch on the rocker studs.

once the lifter pumps up all that stuff moves together how would a 1/2 turn actually increase stress on the lifter and particularly the oil metering disc (the thing that failed).

Preload was 1 turn I set it to 1/2, way after the fact. I don't know the thread pitch on the rocker studs.

once the lifter pumps up all that stuff moves together how would a 1/2 turn actually increase stress on the lifter and particularly the oil metering disc (the thing that failed).

#26

wow I actually did something right i guess.

Preload was 1 turn I set it to 1/2, way after the fact. I don't know the thread pitch on the rocker studs.

once the lifter pumps up all that stuff moves together how would a 1/2 turn actually increase stress on the lifter and particularly the oil metering disc (the thing that failed).

Preload was 1 turn I set it to 1/2, way after the fact. I don't know the thread pitch on the rocker studs.

once the lifter pumps up all that stuff moves together how would a 1/2 turn actually increase stress on the lifter and particularly the oil metering disc (the thing that failed).

1/2 would be a problem. When you approach 1" this adds stress through over-compressing the plunger mechanism. Doing reduces the "give", if you will, within the lifter. Think of it, as "bottoming out" like when your car bottoms out by taking a dip too fast. Also, by increasing that pre-load, you reduce the volume of oil within it and any given time.

What size studs? That is, what is the nut size 3/8-24, 7/16-20 etc.

Assuming a 7/16 X 20 stud, 1 complete turn equals .050" of compression. That is, the nut travels downward .050". Now, assuming a 1.6 ratio rocker...050 X 1.6 = .080. This is to much based on my earlier mention or .060-.070. Therefore, 1/2 turn is .0250 X 1.6 = .040.

See how this works? To a degree, too looses is better than too tight. To further complicate matters, every engine is different. However, a constant in all is proper P/R Geo.

This assuming "0" lash , "0" play in the valve train.

What I look for, as well is how many inches of vac. is the engine producing at idle? Too tight of a valve train, reduces engine vac. I found this out long ago when I saw the vac my cam was capable of making was low. I learned that my pre-load was too tight. I loosened the rockers and my idle vac rose to the number specified by my grinder, 16.7", at least I think, this is the number. Haven't needed to go back check.

Thread

Thread Starter

Forum

Replies

Last Post